The most advanced press fabric family

Infinity press fabrics

The most advanced press fabric family

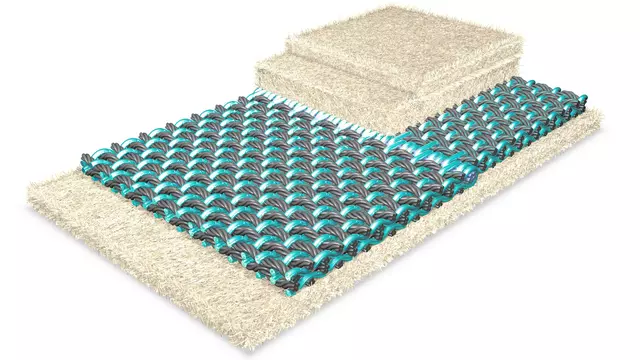

Voith’s Infinity press fabrics are designed for the most challenging applications in today’s world of papermaking. A full line of advanced press fabric designs suit every machine configuration and customer expectation.

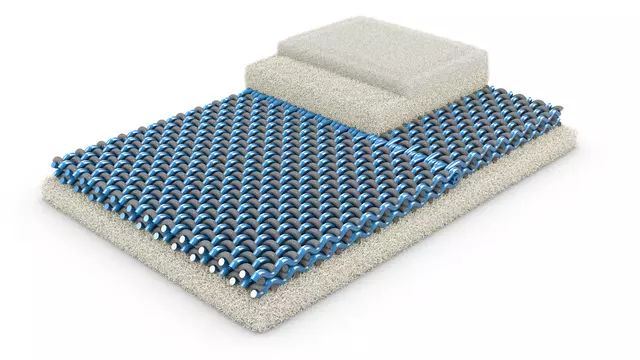

Infinity press fabrics have an especially uniform, high-quality base fabric that results in a laminated structure with the ability to maintain void volume throughout operation. Infinity is the best choice for your paper machine.

Benefits

- Steady performance over lifetime, reliable outputs

- Increased fiber anchorage

- Opportunity for optimized nip dewatering

- Reduces fiber loss even at the end of the felt life

- Part of AdvancedPRODUCTS

Fast installation: engineered seam zone

Infinity products can be ordered with or without a seam. The Infinity seam loops are perfectly formed with identical loop length roundness and spacing.

Better sheet quality: pressure uniformity

The base offers a high degree of contact points and base uniformity.

Clean run: high compressibility

The Infinity base interaction allows for high compressibility and resiliency to improve dewatering and keep the fabric clean.

Perfect fit: extraordinary width stability

Attributable to the manufacturing process, the base fabric provides excellent in-plane stability.

Quick start-up: steady state operation

Desired machine speeds are reached faster due to the laminated structure of the fabric.

Fiber anchorage: cabled yarn

The fiber anchorage is highly improved thanks to the new material and technology. It can be used as seamed and endless and has the most efficient twist level in the base fabric with mono loops in the engineered seam area.

Infinity product range

Infinity product range sorted by customer basis weight

Infinity

Infinity

Infinity is a full line of endless and seam press fabrics for highest performance on paper machines.

The characteristics increase the dewatering performance and reduce dirt deposits and fiber loss over lifetime.

Infinity is the most advanced seam concept on the market! The loop size in combination with the Voith-developed anchorage yarn and carefully sized seam closure pintle result in the lowest potential seam marks.

Infinity ToughLine

Infinity ToughLine

Designed especially for the most challenging applications, our Infinity ToughLine can withstand the most extreme conditions.

ToughLine is available for all Infinity fabrics and creates excellent compressibility resistance through its laminated structure. In conclusion, Infinity ToughLine delivers a reliable outcome throughout the fabric lifetime.

Infinity FineLine

Infinity FineLine

Infinity FineLine has the finest loop size on the market and simultaneously offers superior seamability due to the engineered seam zone developed and patented by Voith.

Infinity KenosLine

Infinity KenosLine

Machine dewatering is maximized and water savings are achieved by maintained void volume due to the innovative modular double-layer structure built into the Infinity family press fabric designs.

Infinity KenosLine is also very dimensionally stable in low pH, high temperature conditions, exhibiting additional benefits such as excellent life, water savings and a steady production output on which the customer can rely.

Voith offers the four-layer Infinity KenosLine with a single robust seam and in an endless variation. The modular structure of the fabric allows it to be tailored precisely to the customer requirements.

Your contact for press fabrics

How can we help you? Talk to your personal expert:

Upgrade your press fabrics

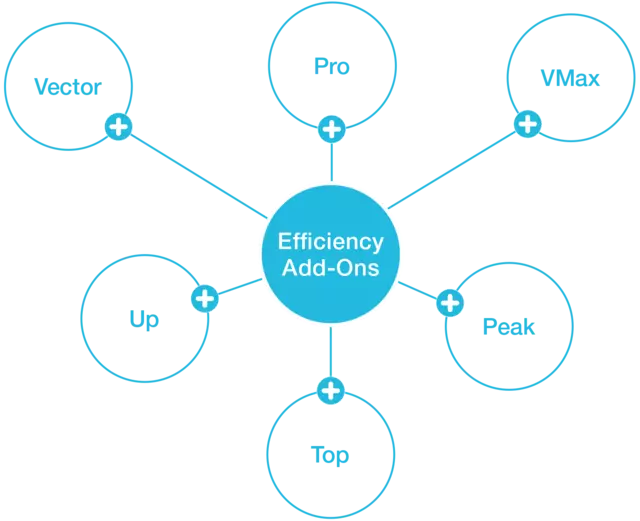

All Infinity designs are available with our efficiency add-ons

Our modular Efficiency Add-Ons for press fabrics address different requirements in paper production and increase the efficiency and/or performance of our felts.

- +Up guarantees a smoother and especially faster startup performance. These positive aspects result in increased production and stable running conditions.

- +Peak technology is a unique Voith developed application of elastomer material for press fabrics. With +Peak, the felt does not permanently deform. This guarantees more resilience and a maintained caliper and void for consistent overall efficiency. Additionally, +Peak will help to achieve great lifetimes.

- +Pro has an excellent, smooth and non-marking premium surface with high wear resistance and stable running conditions. These improvements guarantee high-quality paper with best printability properties.

- +Top was developed to supply an optimized seam package to ensure best paper quality and significantly less seam marks.

- +VMax incorporates a new multi-dimensional base component with alternating dynamic filaments to support strength and stability for an increased open press fabric structure.

Our Infinity family is part of Voith’s AdvancedPRODUCTS

In addition, our Infinity family is part of Voith’s AdvancedPRODUCTS, which means that perfectly fitting products are available to improve the papermaking process and maximize savings.

Find all information about the most advanced press fabric family in our brochure

- Infinity product range

- Infinity 2 & 2S: Dynamic press fabric for fast start-up

- Infinity 3 & 3S: Great dewatering and sheet smoothness

- Infinity 4 & 4S: Built for challenges

- Infinity Res & Res S: Extraordinary width stability

- Infinity Advance & Advance S: Controlled dewatering

- Add-Ons

Engineered for success

Voith provides fast and easy seaming as a result of Infinity seam loops, which are perfectly formed with identical loop length, roundness and spacing. Infinity scores big with high efficiencies in decreasing installation time and time reqiuremented for overhead crane usage.

Learn more about how Voith is challenging this main goalsExplore other relevant products, services and industry solutions

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now