For more efficient farming, automation is the future.

The global agricultural sector is facing enormous challenges. It needs to feed a growing world population while sparing resources and adapting to climate change with all the associated side effects like drought and extreme weather events. The megatrends of electrification, automation and digitalization will provide important keys to the solution in the future. The goal must be to increase efficiency in agriculture. Voith subsidiary ARGO-HYTOS offers customized solutions and cutting-edge concepts for assistance and automation systems.

Feed more people and survive climate change

Change as a constant companion: For farmers, the fact that the world is changing is nothing new. Data, facts and figures on challenges already mastered and still to be mastered.

The world population is growing In the UN’s medium-scenario projection, up to 11 billion people will need to be fed in the future – more than two billion more than today.

Source: United Nations, World Population Prospects 2022

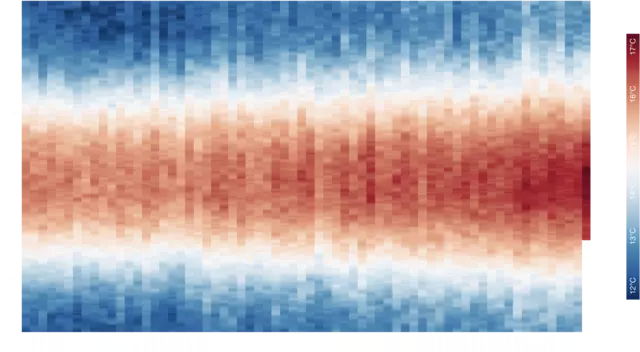

A new temperature record almost every year: Climate change is having an increasingly greater impact worldwide. 2023 could be the first year in which the 1.5-degree threshold is exceeded.

Source: JRA-55 – the Japanese 55-year Reanalysis, Japan Meteorological Agency

Bringing more efficiency to the field

These are remarkable facts and figures whether you are looking at the agricultural development curve in the past or considering the challenges of the near future. Most studies and forecasts agree that these figures predict continuing growth in the global population and the increasing impact of climate change. Both these challenges put agriculture under the spotlight.

“The demand for food will continue to grow worldwide,” says Dr. Lars Brinkschulte, Head of Systems & Innovation at ARGO-HYTOS. “If the agricultural industry is to feed 10 billion people in the future, the entire agricultural process chain must become even more efficient.” To do this, a lot of adjustments are being made simultaneously. Firstly, it is important to avoid damage to harvests, for example by making crops more heat-tolerant and able to do with less water. In this context, technology also plays a key role. “The more accurately a process step is carried out, the higher the crop yield can be later. This applies to processes ranging from tillage to soil management to the harvesting itself.”

Grain cultivation vs.

grain consumption

Development of global grain production and demand: The total global grain production in 2023 of around 2.3 billion metric tons is approaching a world record. Nevertheless, for years now, consumption has often exceeded production.

Source: International Grain Council (IGC), cited on “AgrarMarkt Austria”

Number of people fed by each farmer,

using the example of the USA.

Source: Statista / American Farm Bureau Federation

(number for 2021)

Yield per hectare

in tons using the example of wheat production in Germany. In the USA, the yields per hectare in grain production could be increased by as much 360% between 1950 and 2021.

Source: Statista

Smart technology is gaining ground in agriculture

Another area of development in agriculture is digitalization. “Huge volumes of data are generated in the agricultural sector. If you analyze these data and the associated processes, you will always find opportunities for improvements,” says Dr. Lars Brinkschulte. To this end, many agricultural businesses use farm management software. “Farmers can use this software from the comfort of the farm office to track the current location of every machine, the work it is doing, and the yield that can be expected. Are there likely to be bottlenecks in the logistics chain between field, farm and grain mill? If you have the answers to these questions you can always make your processes a little bit more efficient.

The technology itself also offers considerable potential. “All megatrends actually play a major role in the agricultural sector, for example through alternative drive concepts like electrification, but also due to the automation of driving and work processes,” says Dr. Dirk Linden, Head of Group Technology & Production at ARGO-HYTOS. “When it comes to the drive system, it is important to be open to technology. Depending on power class and requirements, battery-electric, hybrid (diesel-electric), hydrogen-based or conventional drive systems can be considered. If there is an electrical energy source in the vehicle (battery, fuel cell, hybrid), then the entire technical architecture changes. And in this context, it makes sense to think about using a decentralized hydraulic system that can work much more efficiently if it is adapted correctly to the application. That is what we do at ARGO-HYTOS”, says Dr. Dirk Linden. “However, the truth is that current battery storage systems do not offer enough power for long work shifts in the fields. And such long shifts are simply the norm in the farming sector. Hydrogen storage systems are also easier to integrate into long-distance trucks than into tractors.”

Coming soon: Autonomous farm operations

The development towards autonomous driving and/or autonomous operations is being taken a step further. The first highly automated agricultural machines are already being trialed. “The field is effectively a self-contained area, which makes it easier to carry out tests compared with driving in road traffic. But apart from the driving process, agricultural machines also have other complex tasks to handle. This increases the level of complexity compared to cars and therefore calls for close collaboration between OEM and suppliers. ARGO-HYTOS is a much sought-after consultant and development partner in this area,” says Dr. Lars Brinkschulte.

Automation plays the key role on the road to fully autonomous working. It does not seek to replace the driver. Rather, the point is to use technology in such a way as to allow the driver to achieve the best possible outcomes. The ARGO-HYTOS team currently has an example in its development pipeline of how automation can increase both sustainability and efficiency: a system for the automatic boom control of field sprayers.

Assistance system to reduce workload and optimize processes

“Statutory provisions relating to crop protection are becoming increasingly restrictive, while at the same time, the prices of pesticides are increasing. Anyone spreading pesticides would therefore prefer to use them as little as necessary and to the greatest possible extent in line with actual needs,” says Dr. Lars Brinkschulte. To ensure homogeneous spreading, a defined distance between spray nozzle and plant canopy must be adhered to as closely as possible. In the past, this entire task was done by the farmer. However, the need to focus on both the driving and the work process increases the physical and mental strain, which in the long run can lead to poorer work outcomes.

ARGO-HYTOS has developed its own system that uses ultrasonic sensors to detect the distance to the plants and then adjusts and controls it with hydraulic control technology. The system also isolates the spray bar and machine chassis using hydro-pneumatic suspension technology. This simplifies the mechanical structure and at the same time allows the suspension characteristics to be adapted to the driving and work situation. The farmer can then concentrate on driving the machine. This is an example of just how helpful innovative assistance systems can be.

ARGO-HYTOS is in close contact with the end user. A farmer in the area is providing the developers at ARGO-HYTOS with agricultural test areas and is testing the systems at an early stage of development in field operations. This allows potential system optimizations to be identified at an early stage. The fact that the developers are being directly confronted and dealing with realistic test and operating environments leads to fewer iteration loops in the development of market-compliant system solutions.

ARGO HYTOS

A technology leader in hydraulic system technology

As a component and system supplier, Voith company ARGO-HYTHOS is an important part of the supply chain of leading OEMs in the field of mobile machinery and general mechanical engineering. With its workforce of around 1,600 and more than 75 years experience in control and instrumentation and filtration, ARGO-HYTOS is constantly setting new standards in the hydraulics industry. ARGO-HYTOS has become an innovation leader in the field of mobile hydraulics in particular.

Improving efficiency with intelligent assistance systems:

Current development areas of ARGO-HYTOS.

Hydropneumatic suspension: An adjustable suspension is indispensable for long, fatigue-free work days. Using sensors and intelligent algorithms, the hydropneumatic suspension systems can distinguish between driving on the field or on the road and adapt electronically to different load conditions.

Spray height control: Assistance systems that automatically maintain a consistent distance between spray boom and plants. An additional hydropneumatic suspension attachment decouples the spray boom from the rest of the machine.