2025-10-21 Voith celebrates over 40 years of NipcoFlex technology

- Since its introduction in 1984, NipcoFlex technology has proven itself in over 700 shoe press installations worldwide.

- The technological advantage of the shoe press lies in its high press impulse and optimal pressure gradient, which enable maximum production output and quality.

- NipcoFlex technology minimizes specific energy and production costs, enables high production speeds and ensures efficient drainage.

- Voith combines mechanical components and high-performance press shells in a complete package for maximum performance.

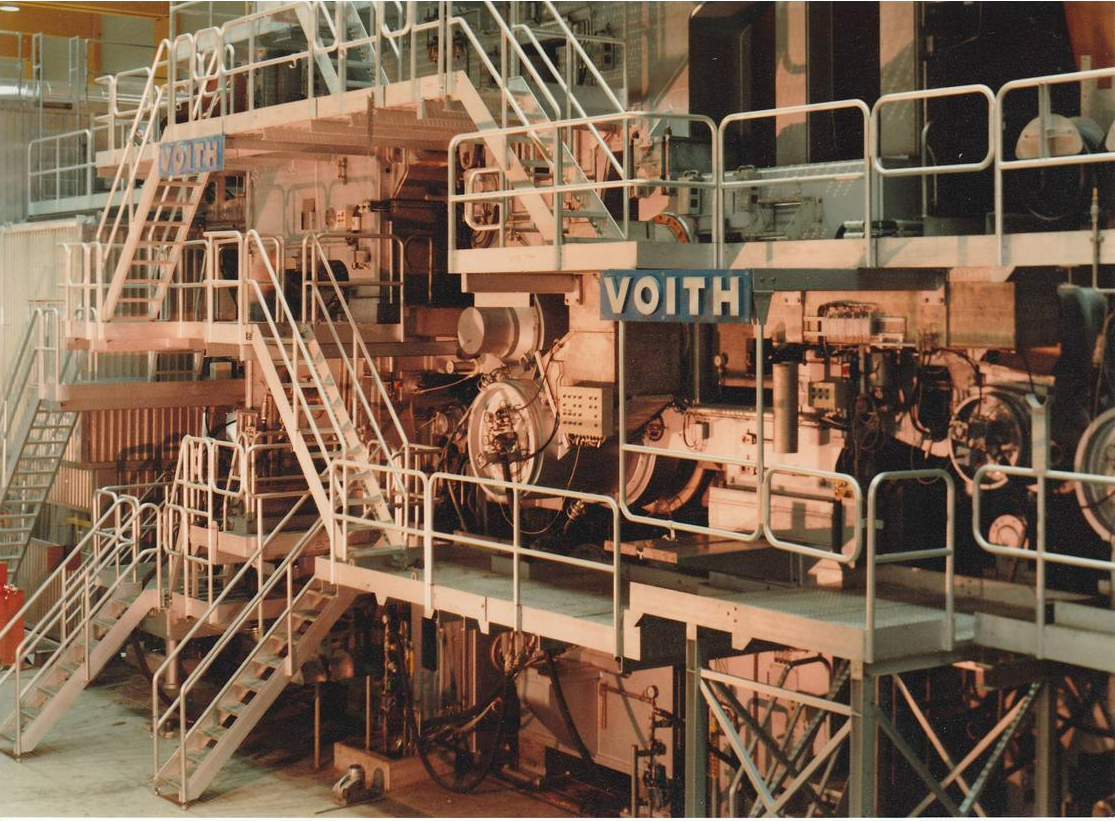

HEIDENHEIM. Full-line supplier Voith celebrated the 40th anniversary of its revolutionary NipcoFlex technology, which has proven itself in more than 700 shoe press installations worldwide since its introduction in 1984. This groundbreaking technology has permanently changed the paper industry by ensuring maximum production output and the highest quality standards.

Dworschak Niklas

Global Communication Manager Voith Paper

m +497321372051

NipcoFlex technology is characterized by its simple and reliable design. The high press pulse to which the paper web is exposed, combined with a long dwell time in the nip and optimal pressure gradients, ensures maximum dewatering performance and minimal re-moistening of the felts. Key features include the design of the hydrodynamic pressure shoe with upper and lower parts and an insulating layer in between. Due to its very low bending stiffness, this ensures excellent line force profiles. The hydrodynamic lubrication gap allows for a continuous and uninterrupted pressure increase, thus preventing damage caused by contact between the shell and the pressure shoe. Reliable and well-designed systems – for jacket pre-tensioning, mounting and adjustment, for example – ensure easy handling of the machine in all operating situations.

Voith is currently developing the next generation of shoe press technology. The focus is on energy savings, improved maintenance and increased performance of felts and covers throughout their entire life cycle. The first important step in this direction is the development of the HighPerformance Press.

The HighPerformance Press concept reflects the absolute focus on resource-saving production. An initial installation is already showing savings of over 4 percent in steam, and an upcoming reference will demonstrate similar savings. Additional features, such as a smart hydraulic unit and reduced drive power also focus on sustainable production, while overall performance and maintenance handling are continuously optimized.

The focus is not only on new installations; existing systems can also be significantly improved in terms of energy efficiency in the future using the new concepts.

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 22,000 employees, sales of € 5.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.