Reliable information about the health status of your machines

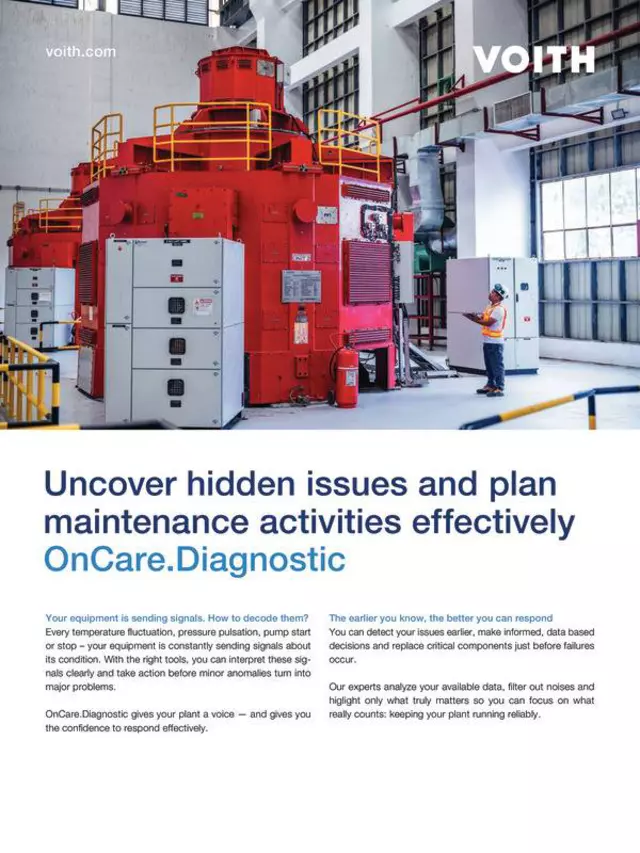

With OnCare.Diagnostic our customers are able to schedule maintenance activities precisely and prevent unplanned shutdowns. The interactive applications enable the integration in the customer asset management structure and the direct communication to Voith Hydro experts. The OnCare.Diagnostic family stands for reliable information about the health status of your machines.

Your challenge is our ambition

- reduce (un)planned outages

- allocate O&M resources

- run diagnosis of your machines

- of missing information

- maintenance is preventive and reactive driven

- diagnosis is time-consuming

- there is a lack of knowledge

- reliable information about the health status of your machines

- dedicated recommendations for actions

- support for problem solving

The solutions of OnCare.Diagnostic

Expert supported decision making via OnCare.Diagnostic Professional

Early anomaly detection through data analytics via OnCare.Diagnostic Base

Optimize maintenance intervalls and increase the hydropower plant availability with Professional

This solution provides dedicated maintenance recommendations for large inspection intervalls. The Digital health assessment and Remote expert support help you to make smarter decision-making for maintenance activities and solve troubleshooting.

Advantages at a glance:

- Increase plant availability

- Effective budget allocation

- Shortened maintenance planning

- Automated calculation of malfunction values

- Trend and event-based analysis of malfunctions

- Root cause analysis as well as warnings and alarms of malfunctions

Deliverables

- >66 malfunction diagnostic values

- Regular Digital Health Assessment reports

- Dedicated maintenance recommendations

- Risk indications on the assets

- Remote expert support

Visualization options

- Easy access to OnPerformance.Lab Interact via MyVoith

- Access everywhere, thanks to the web browser application

- Interactive communication and report structure

How it works

Our OnPerformance.Lab experts Dr. Alexander Jung and Dr. Thomas Mahnke discussed the latest developments in hydropower maintenance and how data science delivers in this framework a forward-looking, innovative solution. Register now and view the exclusive recording of the live event.