Built for performance. Designed for the future.

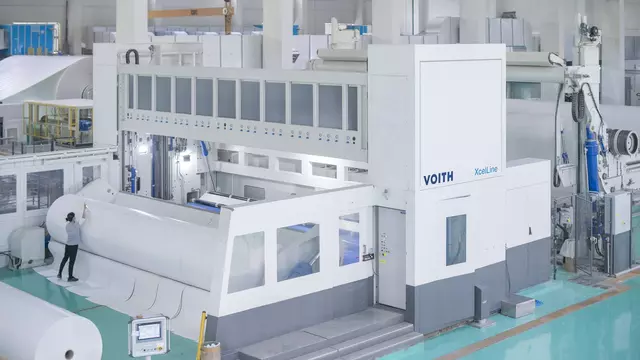

With the XcelLine, Voith delivers paper production at a new level of efficiency, tailored to every paper grade. All components, technologies, and services are seamlessly integrated to ensure optimal performance throughout the entire lifecycle.

Voith’s holistic approach includes reliable auxiliary systems and professional execution. Our Process Line Package (PLP) ensures that even complex projects run smoothly, with reduced risk, lower costs, and clear accountability. And: By digitally connecting products and processes, we enable smarter, more profitable paper production with machines that consistently evolve to meet changing market demands.

At Voith, every customer receives a machine precisely configured to their needs – ready for today, and designed to evolve continuously, ensuring excellence for the future at every step of the way.

Powering progress – all along the line.

The XcelLine sets new standards in paper machine excellence by addressing today’s challenges and tomorrow’s opportunities. It delivers proven reliability and embraces future-proof innovation to support your ongoing success.

Discover the key benefits that make the XcelLine the smart choice for your paper production.

Proven reliability & operational efficiency

The XcelLine delivers fast, on-time startups and ramp-ups, reducing downtime and paving your way to full production capacity. Its modular design allows for easy upgrades and retrofits. This ensures long-term investment security as market demands evolve. Engineered for high machine reliability and availability, the XcelLine minimizes unplanned maintenance, providing a stable production. Integrated full-line solutions – from fiber preparation to finishing – reduce interface issues and guarantee seamless compatibility, unlike competitors who rely on third-party components.

Future-proof performance & innovation

As a smart integration platform, the XcelLine is a seamless bridge to Voith Paper’s digital ecosystem, including the Autonomous Paper Mill. Precision-engineered components, such as the MasterJet 4Tec headbox, ensure superior paper quality with less waste and higher productivity. Resource efficiency, sustainability, and CO2 reduction have become industry-wide goals – and the XcelLine meets these baseline expectations with optimized consumption profiles. Its proactive knowledge transfer programs support your teams with the necessary expertise to allow for continuous process improvements.

Long-term enablement & partnership

Voith goes beyond delivering machines by building long-term partnerships that support your business from project inception through ongoing optimization. With a single point of contact for project execution, we ensure clear communication on timelines, costs, and risks. Our service teams provide tailored solutions and knowledge transfer, empowering your staff to maximize machine potential. Supported by strong local service, Voith’s customer-first approach fosters trust and reliability that competitors find hard to match – making us a partner you can count on for sustained success.

From ramp-up to success – value all along the Line.

From the very first roll to long-term performance, the XcelLine delivers measurable value at every stage. Discover how each core benefit translates into tangible operational advantages for your mill.

Smart, end-to-end integration for the mill of tomorrow.

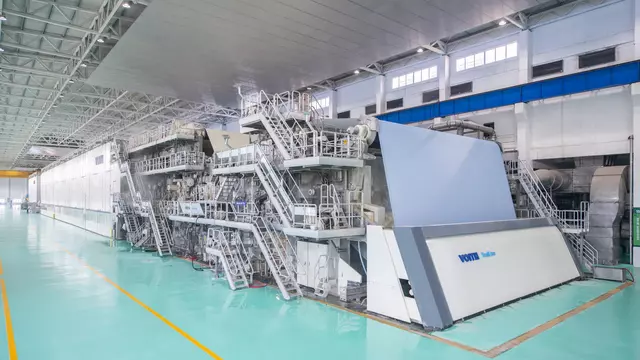

The XcelLine is engineered for seamless end-to-end integration – both mechanically and digitally. As a complete full-line solution from stock preparation to finishing, it eliminates interface problems that are typical of third-party systems, ensuring consistent performance across every section. At the same time, it serves as a backbone for the fully autonomous mill. By bridging directly into Voith’s digital ecosystem MillOne, the XcelLine enables real-time data flow, advanced automation, and continuous optimization. This smart integration creates a future-ready platform that supports stable production today while unlocking long-term digital transformation.

Reliable by design. Best value for money.

The XcelLine is engineered for maximum machine availability, long-term stability, and outstanding return on investment. With over a decade of proven performance across global installations, it delivers high uptime and minimal unplanned maintenance. Precision-engineered components and predictive maintenance tools ensure stable production with fewer interventions. More than just reliable, the XcelLine represents the best value for money in its class: combining technical excellence with deep, long-term partnerships and expert service. The result? A mature, adaptable system that has proven its worth over and over again.

From zero to full speed – fast start-up, efficient performance.

The XcelLine’s industry-leading startup process is engineered to significantly reduce downtime and accelerate the ramp-up phase, enabling your mill to achieve full production capacity faster than competitors. Advanced control systems and real-time monitoring enable precise coordination of all machine sections during startup, minimizing mechanical stress and process variability. This results in a smooth and reliable transition from initial operation to steady-state performance. By optimizing startup sequences and leveraging predictive diagnostics, the XcelLine maximizes productivity while reducing costly delays and resource waste.

Expert service and open communication for lifelong partnerships.

Voith’s commitment to lifelong partnerships is rooted in its family-owned culture, which fosters trust, accountability, and a customer-first mindset. Our expert-led service teams anticipate challenges before they arise, delivering solutions tailored to your mill’s evolving needs. We prioritize knowledge sharing that goes beyond traditional training – embedding operational expertise within your workforce. Combined with a globally coordinated but locally responsive service network, this ensures your operations remain adaptable.

Trust in Voith means partnering with a company that values open dialogue, continuous improvement, and mutual success over mere transactions.

Driven by insight.

Defined by trust.

Our success is measured by the results we deliver and the lasting relationships we build. Through close collaboration and data-driven insights, we help mills overcome challenges and achieve sustained operational excellence. Discover how the XcelLine and Voith’s comprehensive support have empowered customers worldwide to drive performance, reliability, and innovation.

Success backed by Xcellence.

The XcelLine’s proven track record speaks for itself – delivering outstanding results across diverse paper grades and global markets. From the high-speed production at Obbola PM 2 to the specialized tissue capabilities at Beihai PM 2 and the efficiency-driven operations in Green Bay, each installation showcases the XcelLine’s adaptability, precision engineering, and seamless integration. Whatever the paper grade, we’re your experts.

Backed by Voith’s commitment to innovation and support, these success stories highlight how the XcelLine has empowered mills across the globe.

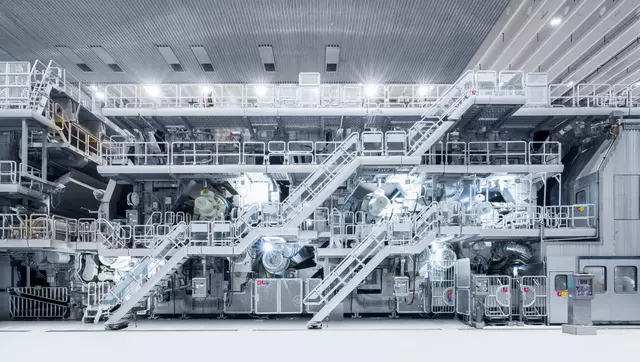

Xcellence by design.

Our XcelLine paper machines were honored as winners of the prestigious German Sustainability Award 2023 in the “Design/Vision” category. To us, this was a beautiful confirmation that our machines are setting new standards with significantly reduced energy consumption, optimized fiber utilization, and markedly lower water usage. Voith’s visionary design study for the future of paper production targets a CO2-neutral process, powered entirely by alternative energy sources and eliminating the need for fossil fuels.

The award recognizes our commitment to pioneering sustainable innovation in paper manufacturing, combining cutting-edge technology with forward-thinking design.