Exceptionally reliable and highly efficient

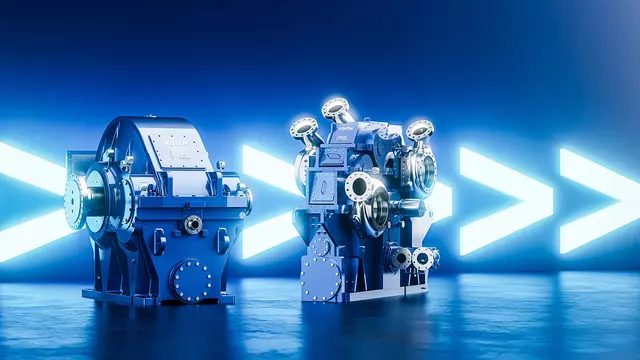

We have the optimum integral gear unit for you, whether in the chemical and petrochemical, or in the oil and gas industry. Voith BHS integral gear units are known for their high-quality features. In addition to being custom-made to your requirements, our solutions provide other benefits, such as lower operating costs and CO2 emissions.

Features and benefits at a glance

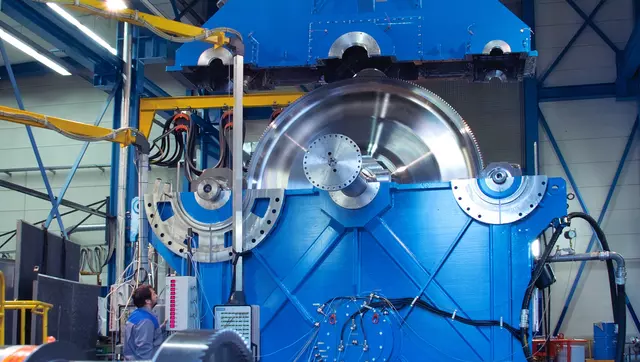

The integral gear unit is the central component and the heartbeat of your turbo gear compressor. Tailor-made to your requirements, these units are manufactured with up to ten compressor stages and weigh up to 70 tons.

Efficiency of max. 98.5 %

Speeds of up to 70,000 rpm

Power transmission of up to 82 MW

Tailored to your technical requirements

Lower operating costs and reduced CO2 emission

Long service life

- Operational reliability, i.e., minimal unplanned stoppages of the drivetrain

- Low vibration values at a super-critical rotor speed

- Extensive experience in rotor dynamic Analysis

- Weight-optimized and extremely torsion-resistant

- Combinable with existing energy sources

- High-quality gear toothing

- Minimized noise level as a consequence of unique gear profiles

Discover your ultimate driveline solution: BHS PerfomanceLine

Compact and optimized plant design

Integral gear units enable compact and optimized plant design as it is possible to combine several compressor and expansion stages onto one gear unit, also known as companders.

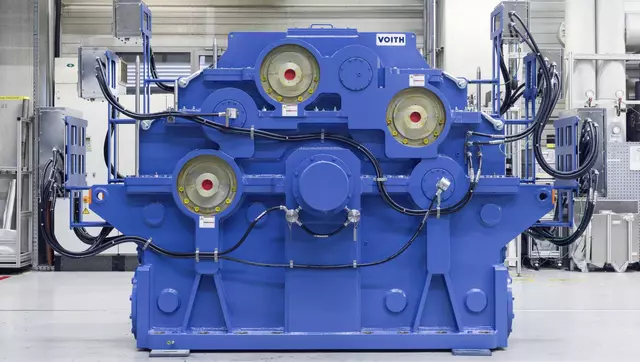

Technical features

Proven technology with outstanding quality, our integral gears are manufactured with up to 10 compressor stages and a total unit weight of up to 70 tons. The gear pitch wheel diameters are over 3 meters, ensuring they perform under the most demanding conditions. Voith integral gear units achieve gear ratios of up to 25:1, and the gear set is typically designed with single helical toothing and thrust collars.

| Power transmissions | up to 82 MW |

| Speed | up to 70,000 rpm |

| Rated output torque | up to 150,000 Nm |

| Compressor stages | up to 10 |

| Efficiency |

up to 98.5% (standard design) up to 99.2% (special combinations) |

| Gear ratio | up to 25:1 |

| Housing design | cast, welded |

| Toothing |

single helical with thrust collar (standard), single helical with separate axial bearing |

References

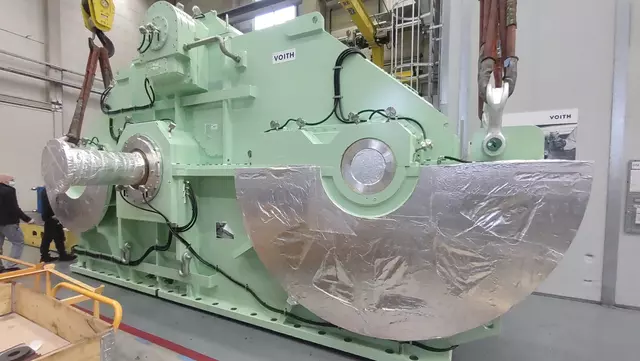

Type WGC5-480TZ

Type WGC5-480TZ (P = 82 MW) the largest integral gearbox from Voith BHS with idler gear and turbine drive for the production of terephthalic acid (PTA)

- Application: Production of terephthalic acid (PTA)

- Power: 82,600 kW

- Speeds: up to 10,238 rpm

Type WGC3-110

Type WGC3-110 (P = 5.4 MW) for reliquefication of natural gas on LNG tank ships

- Application: Reliquefication of natural gas on LNG tank ships

- Power: 5,400 kW

- Speeds: up to 25.555 rpm

Type WGE6-150

Type WGC6-150 (P = 3.5 MW) with 5 pinion shafts for H2 compression and a speed of up to 50,331 rpm

- Application: Hydrogen compression

- Power: 3,537 kW

- Speeds: up to 50,331 rpm

Type WGC5-150

Type WGC5-150 (P = 13.6 MW) for CO2 sequestration with a speed of up to 29,448 rpm

- Application: CO2 sequestration

- Power: 13,602 kW

- Speeds: up to 29,448 rpm

Product registration

In order to receive quick technical support in the event of service, we recommend registering your Voith product. You can scan the QR code on the product or click on the button below to register your turbo gear unit or component. Please provide us your contact details, the product name, the KVO number and optional the date of commissioning.

Voith Service

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability

Voith Turbo Newsletter

Sign up for the Voith Turbo newsletter and get exclusive insights into the world of drive technology. You'll receive regular updates on:

- Voith Turbo's latest products and solutions

- Industry trends and applications

- Upcoming events and webinars

By subscribing to our newsletter, you'll stay ahead of the curve and learn how Voith Turbo can help you optimize your operations.