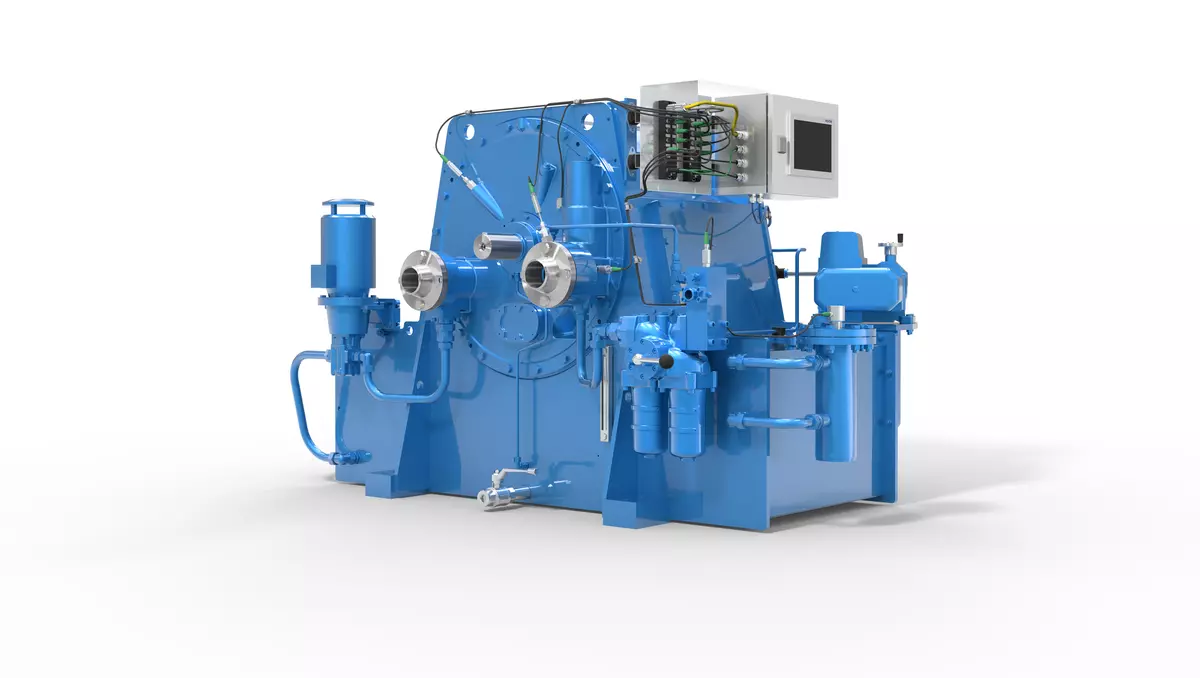

Proven and reliable speed control

Controlling drive line speed and ensuring consistency, Voith variable speed couplings are proven in the field and are particularly well suited for pump, fan, and compressor applications. Simple in design with a robust structure, these couplings operate reliably in virtually all environments.

For precise and step-less speed control of motor-driven machines within a power range from 100 kW to 35,000 kW and with input speeds up to 3,600 rpm, Voith’s variable speed fluid couplings provide you with one of the best-documented solutions on the market with over 15,000 installations worldwide.

Benefits at a glance

Increased reliability

of the entire drive train

Dampening

Shock and vibration dampening

Robust design

suitable for outdoor and extreme conditions

Two-in-one

Speed control and oil lubrication system

Energy saving

Powerful efficiency

30 years

Long lifetime of up to 30 years

OnCare.Health IOLIS

Enabling easy monitoring of operating data, OnCare.Health IOLIS is a compact measurement system for variable speed couplings. It transmits process data from the coupling digitally to the control room via bus protocols such as ProfiNet, ModBus TCP, and Ethernet IP. This system can be seamlessly integrated into both existing and new couplings.

The home screen clearly displays temperature, pressure, scoop tube position, trends, and irregularities, allowing early identification of anomalies. This early detection facilitates corrective action before potential failures occur.

Benefits

- Smart and simple sensor system

- Minimal wiring

- Easy maintenance and handling

- Quick and precise data transfer

- Fast replacement

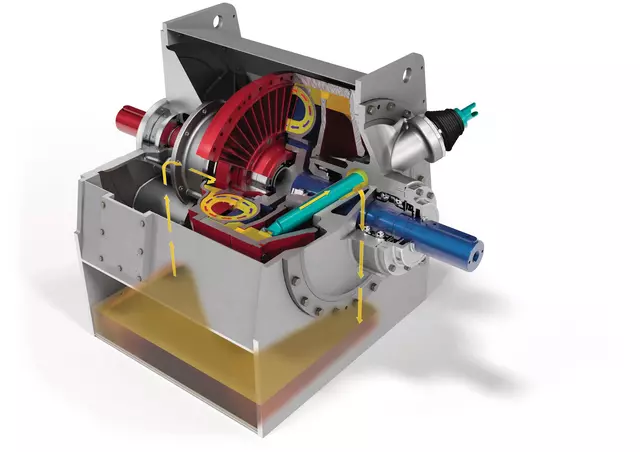

How a variable speed coupling works

Voith variable speed couplings are fluid couplings. They link the drive machine

Voith variable speed couplings are fluid couplings. They link the drive machine – generally an electric motor – with the corresponding driven machine.

The power is transferred through the fluid energy of the working fluid. This fluid flows in an enclosed working chamber between the pump wheel (linked to the input shaft) and the turbine wheel (connected to the output shaft). The coupling fill level can be adjusted between 0 % and 100 % during operation, enabling precise and continuously variable-driven machine speed control. The control range depends on the load characteristic (torque to speed ratio).

Areas of application

Our variable speed couplings are primarily used in pump and fan drive applications within the power, oil, and gas industries and the mining and material production industries.

Further applications:

- Chemical industry

- District heating plants

- Iron and steel industry

- Water management

Publications

-

The right speed. Variable speed fluid couplings

PDFEnglish Chinese German Polish Portuguese Portuguese Russian -