Engineered to perform. Trusted worldwide.

Voith Pulleys deliver unmatched reliability, tailored engineering solutions, and the strength of more than a century of expertise in belt conveyor technology.

Why Voith Pulleys make the difference

Reliable performance

Precision engineering for seamless integration and optimal conveyor operation

Premium quality

Highest-grade materials and components

Maximum uptime

Designed for extended service life

Global network

Immediate support when needed

Massive capabilities

Available in diameters up to 3 meters and weight up to 100 tons

Mining expertise

More than 100 years of experience in conveyor design and operation

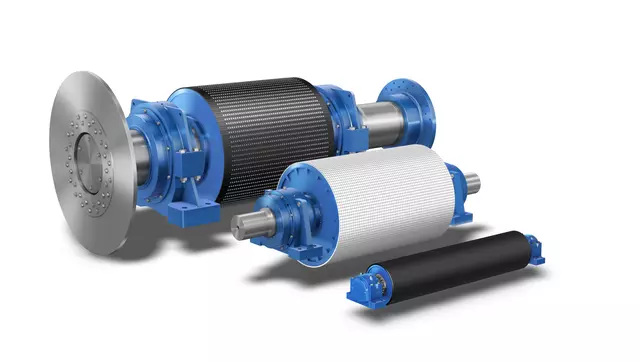

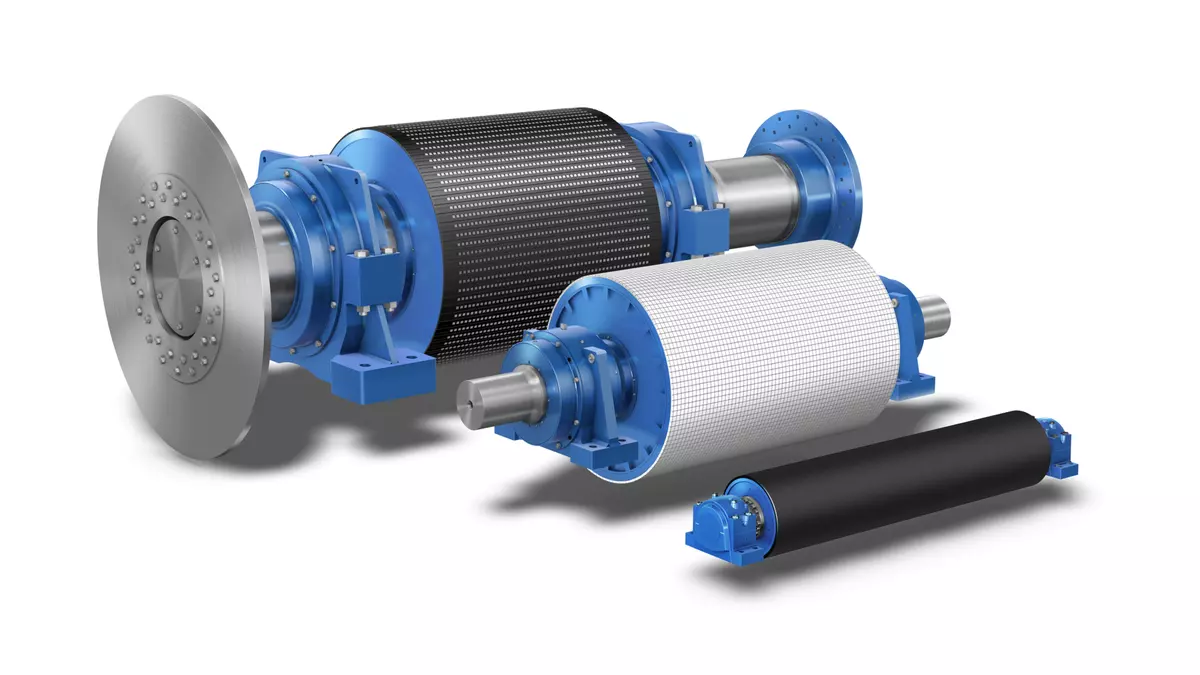

Product details

Voith Pulleys provide versatile solutions for any conveyor system. With multiple lagging options and shaft designs, you can tailor every detail to your specific requirements. Discover what sets our engineering apart.

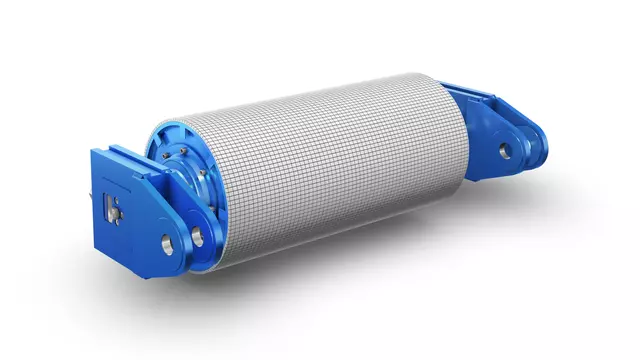

Voith’s standard pulleys are conventional pulleys from the catalogue, that are suitable for use as drive, bend, tail, snub, or take-up pulleys. They are a cost-effective solution for standard conveyor applications.

Voith’s engineered pulleys are calculated and designed to fit your application. They connect easily to existing drive packages, backstops or brakes.

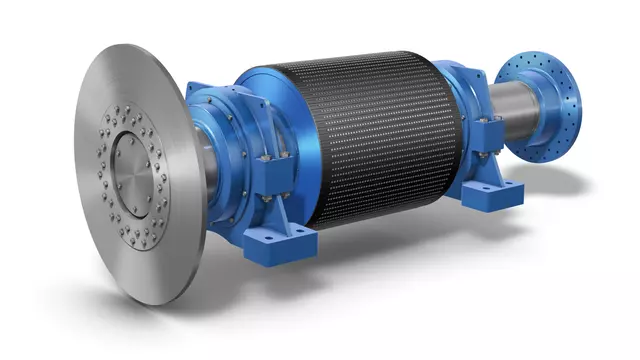

Voith’s gearless drive pulleys are pulleys with extensions that allow the motor to be integrated directly onto the shaft, resulting in very low shaft deflection. We can provide the pulley with brakes, couplings, and other accessories on the shaft ends.

In Voith’s dead shaft pulleys, the shaft remains fixed while the bearings are mounted inside the pulley body. This compact design reduces installation space, lowers costs, and simplifies alignment.

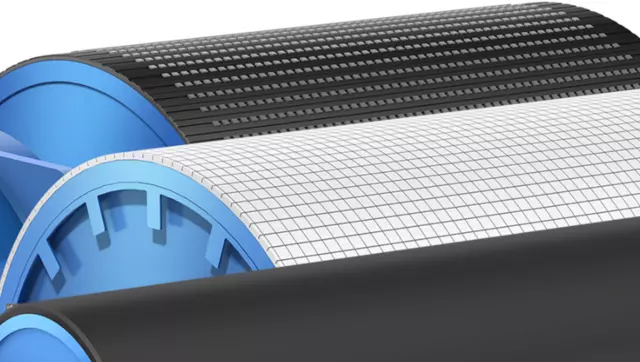

Voith Pulleys are available with a wide range of high-performance lagging types, including ceramic, rubber, rubber-ceramic, polyurethane and custom solutions. These options maximize traction, extend belt life and prevent slippage in even the most demanding applications. Our experts will help you select the right lagging for your needs.

Technical details

| Pulley diameters | up to 3000 mm |

| Width of pulley body | up to 4000 mm |

| Load range | 10-4000 kN |

| Design option | Dead shaft / live shaft / gearless |

| Conveyor location | Drive, bend, tail, snub, tension pulleys |

| Pulley design | Standard welded and high-tension T-Bottom design |

| Lagging | Rubber, rubber-ceramic, ceramic, polyurethane, custom |

| Tolerances | CEMA, DIN |

| Certification | Explosion protection according to ATEX |

Applications

Voith Pulleys are built to perform in the most demanding industries worldwide. From mining and metals to processing and cement, our solutions run reliably under the toughest conditions.

Mining

Built for the world’s harshest environments, Voith Pulleys excel under heavy loads, extreme temperatures, and abrasive conditions. Certified for use in hazardous and explosive atmospheres, our pulleys provide exceptional durability and reliability, reducing maintenance costs and maximizing uptime for critical mining operations.

Metals

In the demanding metals industry, Voith Pulleys deliver high performance even when exposed to heat, dust, and heavy-duty cycles. Precision engineering and top-quality materials guarantee optimal traction, reduced downtime, and efficient material handling, helping you achieve peak productivity in every phase of metals processing.

Processing

Whether handling bulk materials or complex process flows, Voith Pulleys offer precise engineering and customizability for processing plants. Our pulleys ensure smooth, trouble-free operation and minimal maintenance, even under varying loads and challenging conditions. Designed to be easily maintained and optimized for integration, they enhance system availability and keep your processes moving.

Cement

Voith Pulleys are engineered to withstand the high dust loads, abrasive materials, and continuous operation typical of cement plants. Our robust designs and specialized lagging minimize wear, prevent slippage, and deliver the long service life and reliability demanded by the cement industry, keeping your production running smoothly and efficiently.

Download

Voith Service

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability