Modular concept with hybrid technology

In the hydrogen compression segment, Voith has identified several fields of application for the future that facilitate an efficient reduction of CO2 emissions. The focus will be on the development of innovative solutions specifically for trailer filling, refueling station infrastructure, and pipeline compression. Hydrogen refueling stations in particular play a key role in the infrastructure for green hydrogen. This is where cars, trucks, buses or trains can be filled with gaseous hydrogen that then allows them to be operated in a sustainable and environmentally friendly manner.

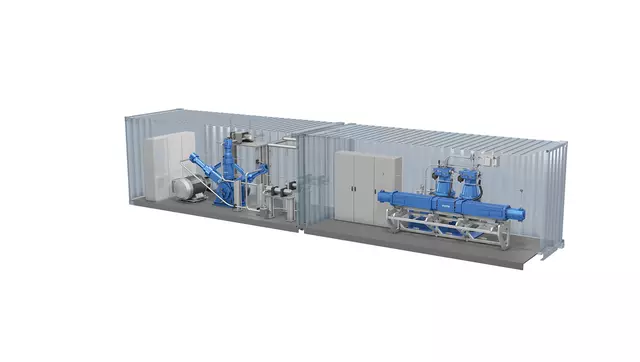

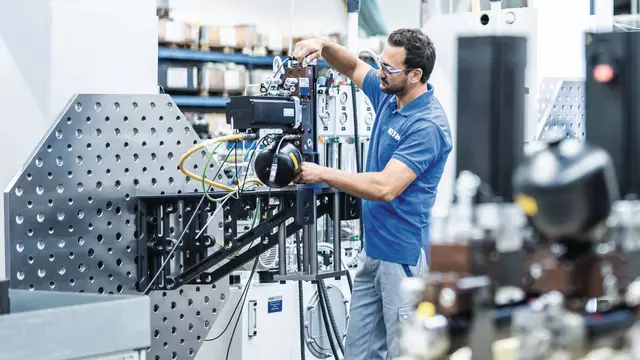

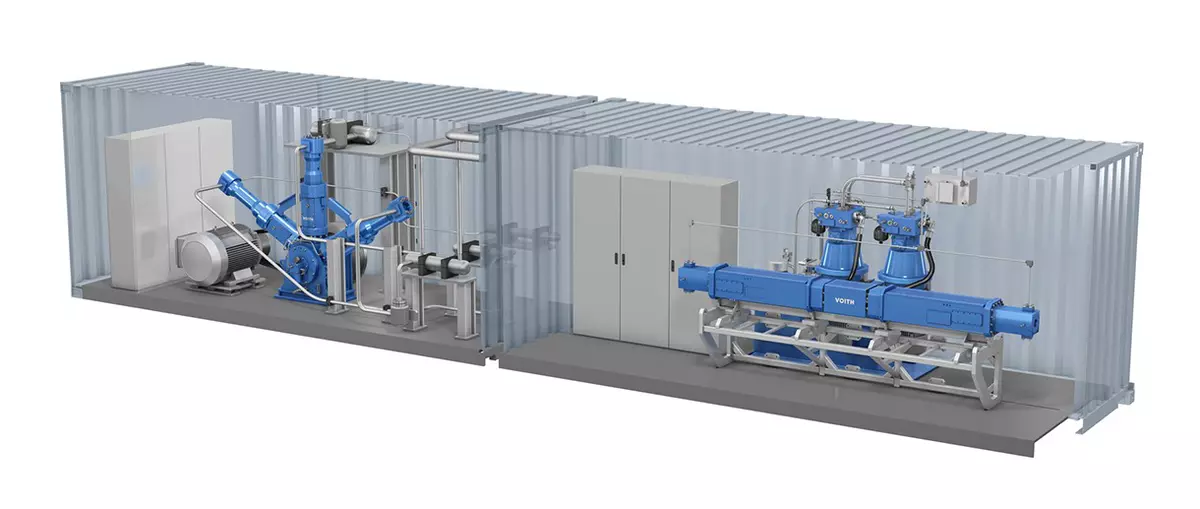

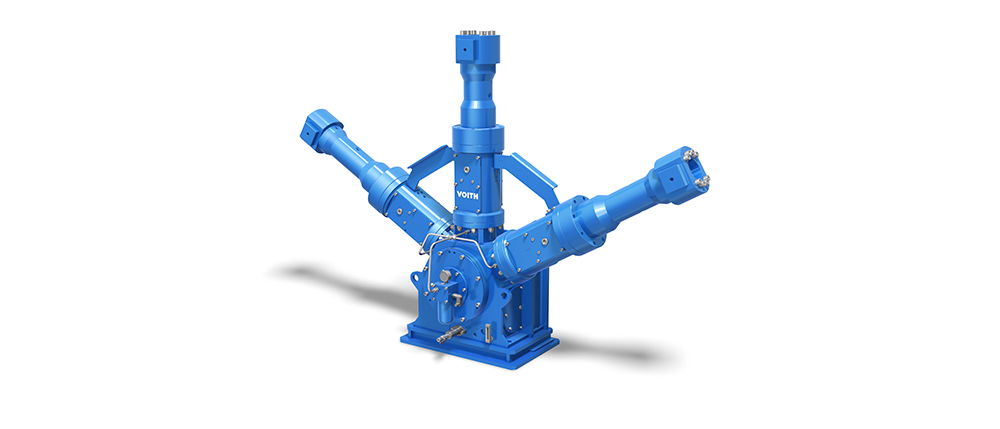

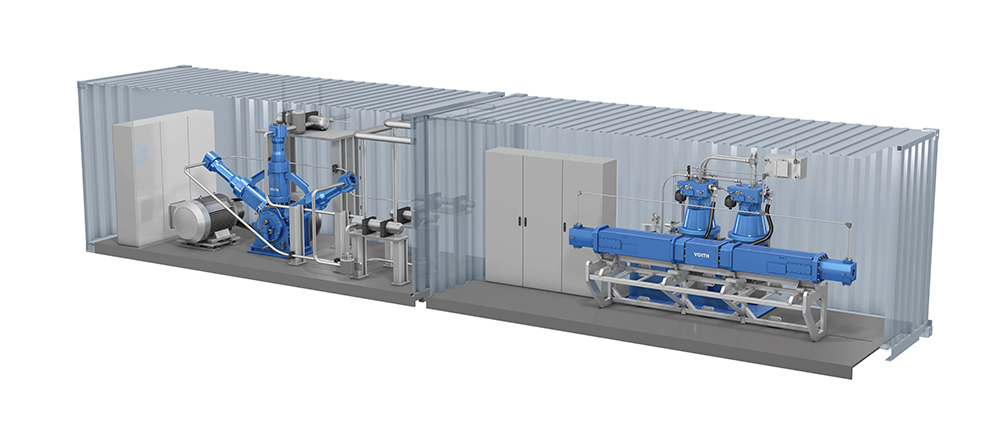

As part of its strategic partnership with Mehrer Compression GmbH, a leading specialist in dry compression of process gases, Voith is currently developing a modular concept with hybrid technology (mechanical and hydraulic) for use in hydrogen compression. As a family-run company, Mehrer is what is known as a “hidden champion” when it comes to oil-free compression and is contributing its expertise and more than 135 years of experience to this alliance.

Your main benefits at a glance

The hydrogen refueling process calls for innovative compression solutions that ensure fast and efficient fueling. Alongside its collaboration with Mehrer, Voith is therefore working with other well-known partners on compressors that allow the compression of hydrogen up to pressures of 900 bar. The following benefits of these new Voith compressors will help to establish hydrogen as a viable and promising energy source for vehicles.

High compression efficiency

The modular concept with hybrid technology (mechanical and hydraulic) ensures high compression efficiency – coupled with a large mass flow rate of up to 300 kg/h.

Higher energy density for greater range

The storage of hydrogen under high pressure increases the energy density and consequently, the driving range. The storage pressure in heavy duty transportation trends towards 700 bar.

Oil-free compression

The new Voith compressors also offer oil-free high-pressure compression and thus ensure the highest hydrogen purity for a longer fuel cell service life.

Reliability and durability

These are crucial factors for the smooth operation of hydrogen refueling stations: The new Voith compressors are capable of working for long periods without downtime.

Fewer costs and CO2 emissions

Thanks to a lower leakage rate with optional re-compression, the new Voith compressors have a higher efficiency and use less energy to compress the gas, saving additional costs and cutting CO2 emissions.

Supplementing the existing product range

Thanks to its hydraulic systems produced in-house, Voith already has sound drive expertise in the field of hydraulic hydrogen compression. The current focus is therefore on the development of new H2 high-pressure solutions and on supplementing the existing product range with mechanical reciprocating compressors for hydrogen applications up to 500 bar and hydraulic compressors up to 900 bar.

High capacity

With Voith’s new mechanical and hydraulic compressors, a high capacity of up to 300 kg hydrogen per hour can be achieved.

Cutting-edge processes

These cutting-edge processes are essential to support the future deployment of hydrogen vehicles and encourage sustainable mobility.

Important building block

Whether mechanical or hydraulic, the new Voith compressors for hydrogen refueling stations are an important building block for the future of emission-free transport.

Technical data

Voith is working on new mechanical and hydraulic compressors for hydrogen applications in two modular package types: the 500 bar compressor package and the 900 bar compressor package with hybrid technology.

| Type | Output | |

|---|---|---|

|

500 bar compressor package A mechanically powered reciprocating compressor developed jointly with Mehrer |

500 bar at up to 300 kg/h |

|

900 bar compressor package with hybrid technology |

900 bar at up to 300 kg/h |

Voith Service

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability