2025-07-15 New Prevo solution from Voith enables upgrade for fast and safe transfer even in confined spaces

- Compact solution for tail threading from press to dryer section is now also available for existing plants with limited installation space

- Increased operational safety through mechanical pickup and transfer of the tail

- Fast tail threading processes increase plant availability

- Metsä Greaseproof Papers is convinced of the advantages on PM 5 in Düren

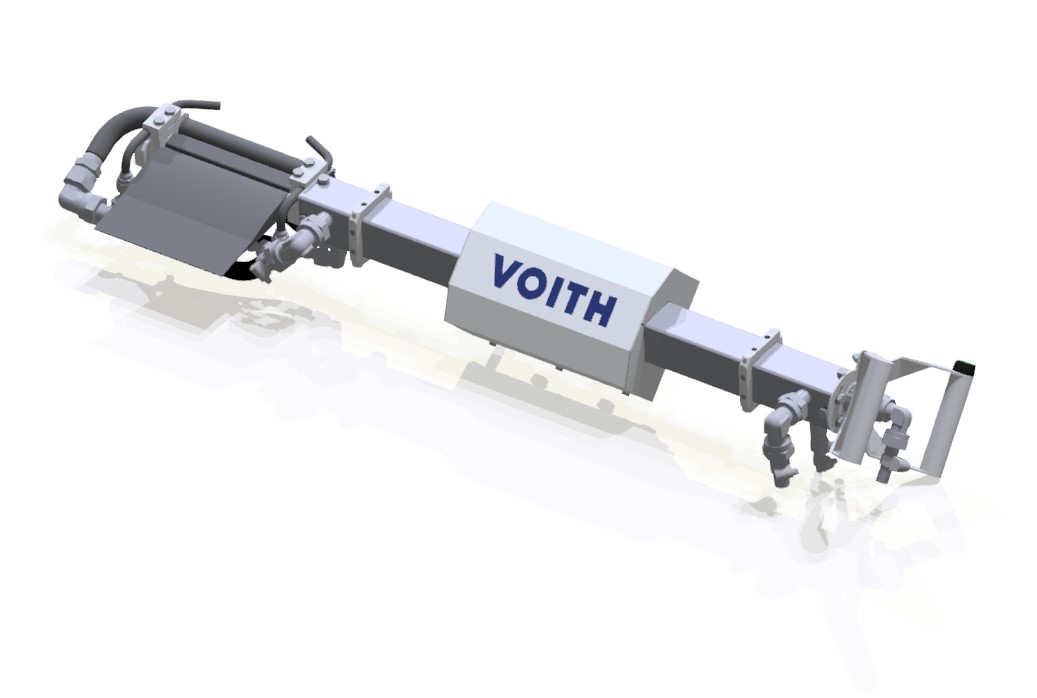

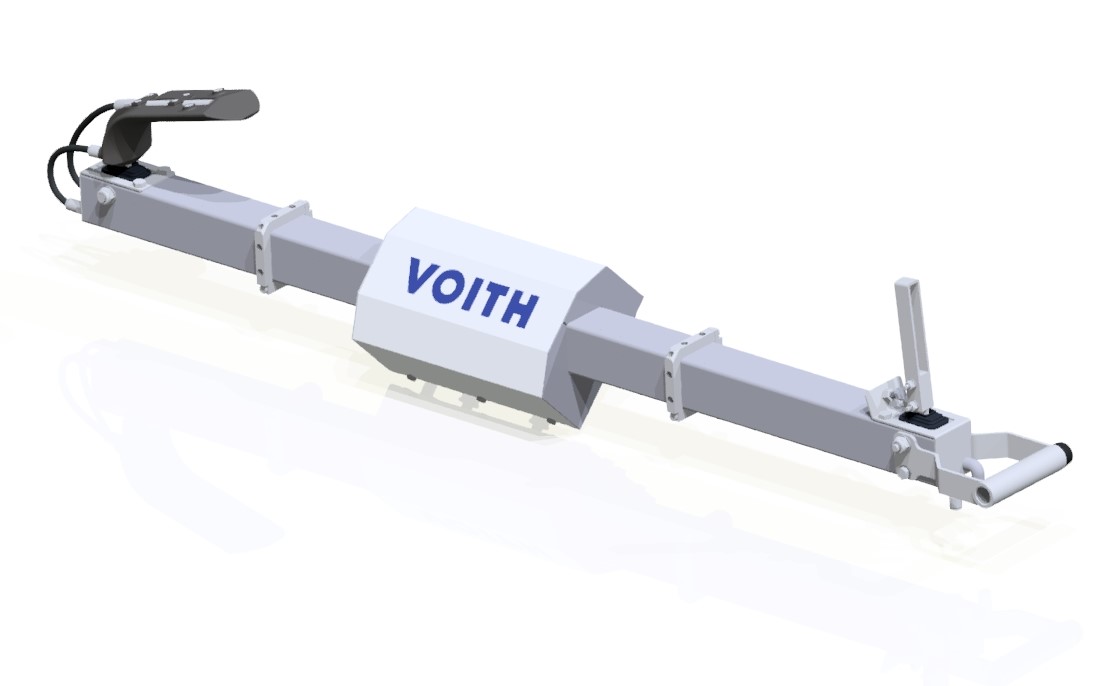

HEIDENHEIM/DÜREN. With more than 1,000 installations worldwide on new and existing paper machines, Voith's Prevo solutions are the proven choice for efficient and safe tail threading within the paper machine. Voith has now launched a new, compact Prevo retrofit solution for the press section that addresses the limited installation space on some existing machines. Papermakers with smaller lines can now benefit from the tail threading solution that eliminates the need for manual intervention and thus makes the entire process safer, more reliable and more efficient.

One of the first customers to use the more compact Prevo tail threading solution is the Metsä Greaseproof Papers GmbH in Düren. There, Voith has installed the new transfer solution from the press section to the dry section on PM 5. The specialty paper machine produces around 40,000 tons of grease-proof paper for baking, cooking and food packaging every year.

Tamara Lemm

Junior Manager Global Communication Voith Paper

t +49 7321 37 9940

The advantages of the solution have been clearly confirmed in operation in Düren:

With the Prevo solution, the tail can be transferred in two steps after a sheet break or shutdown. First, the system peels the tail from the press roll using blowpipe technology and transfers it to the dryer section. In the second step, a deflection arm picks up the sheet from the open draw and transfers it to the ropes. Since the process requires no manual intervention in the machine, it is significantly safer than conventional methods.

In addition to the equipment, Voith also offers comprehensive global service for all components of the Prevo family. Voith experts inspect and optimize the efficiency of the entire transfer process with all products involved and review the safety of the system. At the same time, spare and wear parts are replaced according to the maintenance schedule. In addition, the operability of the transfer process is checked and optimized if necessary.

More information is available at: https://voith.com/corpen/papermaking/tail-threading-and-cutting.html

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 22,000 employees, sales of € 5.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.