Tail Threading and Cutting

Safe and reliable threading and cutting

Due to inefficient threading processes, up to 60 minutes of production time can be lost after each break and startup. In addition, there is often a safety risk for personnel who must undertake a manual intervention in this process. Therefore, we have developed Prevo, fully automated threading and cutting systems. They ensure the highest level of safety for operating personnel, reliable threading processes and short threading times.

Your benefits with PrevoSystems

- Higher runability and productivity due to short threading times

- Increased safety for operating personnel due to fully automated systems

- Easy operation

- System pre-settings allowing functionality on a large range of grades and speeds

- Reduced production loss after a restart of the paper machine

- Short amortization time

Get to know our patented vacuum technology

Best vacuum solution – Optimal tail control for best threading results

- New vacuum source, venturi solution

- Zone controlled vacuum, tail control starts on the first zone

- Clever designed vacuum concept, fits for limited space

The PrevoThread C conveyor is divided into separate zones, which are able to create the full vacuum effect by covering the zone with the paper tail instead of covering the full length of the conveyor to have the full vacuum effect. Due to the zone design, we are able to optimize the tail control from the start and maintain it until the end, instead of getting control after it is too late to have best results. The first zone is equipped with a high vacuum to take control and the following zones with lower vacuum to reliably transfer the tail into the rope nip or next conveyor.

Threading solutions for the wet end

PrevoThread WetEnd

Thanks to decades of experience, Voith knows exactly what is required of threading systems in the wet end. This is why we developed PrevoThread WetEnd Systems especially for use in the press or between the press and dryer sections.

PrevoThread CW

Here you can see our PrevoThread CW in action.

Perfect pickup and transfer in press sections

- Pickup direct from the cylinder, no double tail, direct transfer

- Pickup done by blowpipe and/or bullhorn technology

- Vacuum-controlled pickup device

PrevoLift L&T and PrevoLift P&T

This video shows the PrevoLift L&T in action.

Reliable solution for the press section

PrevoLift L&T lift-up on top of the roll:

-

Bullhorn lift-up technology

-

Reliable transfer to conveyer

-

Clean and clever design, not just a tray

Here you can see a short recording of the PrevoLift P&T.

PrevoLift P&T peels direct from the roll:

- Bullhorn peel up technology

- Reliable transfer to conveyer or directly into the machine

- Clean and clever design, not just a tray

Threading solutions for the dry end

PrevoThread DryEnd

The dry area places extreme demands on the equipment. With our PrevoThread DryEnd Systems, we offer you reliable solutions for all sections in the dry end.

PrevoThread C

This animation shows the PrevoThread C in the dry end.

Patented vacuum solution for best threading results

Our PrevoThread C offers best-in-class technology combined with a clever design. The Prevo Conveyor is the best vacuum transfer solution in threading and suitable for all applications:

- Patented, zoned-controlled vacuum solution for best transfer results

- Proven technology with more than 1.000 units

- Designed for your application, unique solutions for your machine

PrevoLift CTR/CRR

This video shows how the PrevoLift works.

World record equipment for fast speed and complex threading

-

Pickup direct from the cylinder, no double tail

-

Direct way to transfer

-

Vacuum-controlled pick-up device

-

Fastest reference up to 2,020 m/min

PrevoLift FT/FTE

This video shows the working principle of the PrevoLift FT.

Made for standard threading applications

The PrevoLift Flip Tray is the most known threading pick-up device in the world. Benefit from the following advantages:

- Reliable stabilization and transfer of the tail from a drying cylinder onto a conveyor

- Clean design, no cylinders and hoses outside the box

- FlipTray design with 25 years of experience in threading

- Complete threading component

PrevoLift FTC

Here you can see the PrevoLift FTC.

Flip and cut process all in one unit

The combination of the flip and cut process offers many advantages:

- Tray and knife always 100% parallel to each other

- Design delivers perfect cut and most reliable transfer

- No risks of misalignment

- Reliable stabilization

- Clean design

Threading solutions for the dryer section

PrevoThread dryer section

For the dryer section, we have developed two options for the threading process: single tier and double tier. Our solution is called PrevoThread TailStabilizer and is a ropeless design for optimum tail threading within the dryer section.

TailStabilizer – Single-Tier Threading

The proven product with hundreds of installations

Our TailStabilizer is the well-known standard equipment for ropeless single tiers. The equipment, including the stabilization role and stabilization box, is specially designed for threading. Our threading solution offers:

- Proven equipment with hundreds of installations

- Fully automated, safe and reliable

- Specially designed rolls and stabilization boxes with separate vacuum zones

- Best threading results

TailStabilizer – Double-Tier Threading

TailStabilizer is used as ropeless threading system in the dryer section.

The perfect solution for double dryer sections

The latest development o our TailStabilizer fulfills the threading demands for heavy board threading as well as fast graphical threading. Specially designed trays and air jets allow the most reliable and safest threading in the double-tier dryer section. This threading solution offers:

- Specially designed peel-up component, as close as possible to the role for maximum peeling effect

- Specially designed air trays to transfer the tail into the next section

- Adjustable for every application

- Fully automated, safe and reliable

Cutting solutions for the wet end

PrevoCut WetEnd

Clean edges of the web without cracks are a precondition to reduce web breaks and lead to increased runability of the machine. Reliable tail cutters for the threading process shorten threading times. Our PrevoCut WetEnd solutions have been developed precisely for this purpose.

PrevoCut H/DH

Single and double head water jet tail cutter

The PrevoCut H and PrevoCut DH cut the tail in the wire or press section to thread through the pre-dryer section with a water jet. The tail cutters are fully automated and designed for easy maintenance due to easy access to the equipment and quick component exchange. Both products offer the following advantages:

- Excellent cutting quality of the tail, independent from production speed

- Compact beam design, stainless steel

- Easy and quick nozzle exchange

- Tail width automatically adjustable

- Low maintenance effort

- The web can be widened with a constant speed

- PrevoCut H pump unit can be used in combination with TrimSquirt

TrimSquirt

Edge trimming in the forming section

Clean edges are a mandatory issue to have a stable machine without breaks in the forming and press section. Uncountable references show that our TrimSquirt is a reliable solution for your forming section.

- Optimal cutting quality

- High operational and jet reliability

- Constant pressure level

- Easily adjustable – manual or automated

Cutting solutions for the dry end

PrevoCut DryEnd

In the dry area, our PrevoCut DryEnd solutions are the ideal choice and perfect complement to our Prevo threading systems. Our products are perfectly matched to each other. The tail cutters are fully automated and designed for easy maintenance due to comfortable access to the equipment and quick component exchange.

PrevoCut DC

Disc cutter tail cutter

The PrevoCut DC is a tail cutter installed in the open draw of two-tier dryer sections. It ensures a flawlessly cut tail. The advantages of PrevoCut DC are:

- Compact beam design, stainless steel

- Park and maintenance position outside the dryer hood

- Easy, safe and quick knife exchange

- Stabilization of the web possible due to air foil

- Tail width automatically adjustable

PrevoCut STC/DTC

High pressure water jet tail cutter

The PrevoCut STC and DTC high-pressure water jet tail cutters cut a flawless threading tail with the aid of a water jet between 600 and 1,300 bar. You benefit from:

- Precise and reliable cut without tears at the edge

- High cross-directional speed, short threading times

- Independent from web variations

- Compact beam design

- Quick and easy nozzle exchange

- No shearing forces on the web during widening of the web

- Automatically adjustable tail position and tail width

This animation shows how the PrevoCut STC works.

This animation shows how the PrevoCut DTC works.

PrevoCut ET

Edge trim cut technology

PrevoCut ET (Professional Evolution EdgeTrim) is a high-pressure water jet edge trimmer that allows the paper web to be cut with an exactly definable width and position. This system offers the following advantages:

- Reduction of breaks due to optimized web edges

- Safe and fast nozzle exchange

Contact us

Do you have any questions? We are happy to help you find the perfect tail threading and cutting solution for your application!

Our Service – Part of Your Business

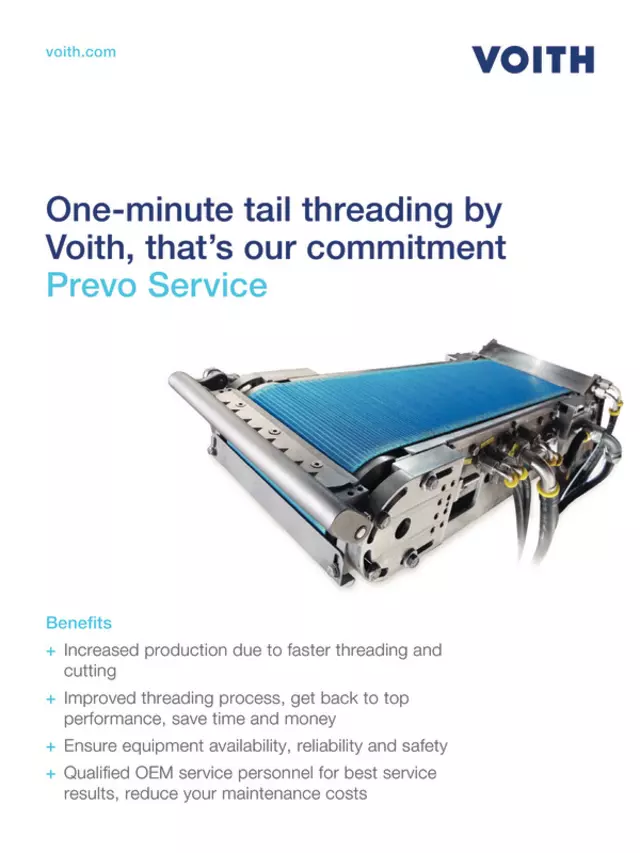

Prevo Service

With our special equipment and process services, we can return tail threading systems to their full operation performance. Our experienced specialists have the knowledge of each component and its effect on the process and can therefore set up your system to its maximum potential. We recommend an annual service to secure best performance and fastest threading success.

One-minute tail threading, that’s our commitment

Voith is the reliable partner for tail threading with more than 1.000 solutions worldwide and over 40 years of experience. Please contact your regional sales manager to discuss how tail threading on your paper machine can be improved. All details regarding our Prevo Service can be found in the product sheet:

- Increased production due to faster threading and cutting

- Improved threading process, get back to top performance, save time and money

- Ensure equipment availability, reliability and safety

- Qualified OEM service personnel for best service results, reduce your maintenance costs

Check out our complete service portfolio

Our service for the paper industry ranges from individual equipment service to maintenance partnerships. Together we will find the right offer for you.