SafeSet offers outstanding precision and reliability by protecting all components in the driveline

Rotating equipment drivelines are long-term investments worth protecting. Every minute of unplanned downtime caused by overload is a loss in production. With outstanding safety and reliability, Voith’s torque limiting couplings protect all components in the driveline, resulting in smooth operation, less wear and tear, and maximum performance of your equipment.

Benefits at a glance

Offering you outstanding precision and reliability through

Accurate release torque

Increases productivity

Compact and customized design

Easy driveline integration

Set torque that remains constant over time

No unwanted releases, which reduces downtime

Instant torque limitation in an overload situation

Protects the driveline and avoids expensive standstill and repair costs

Product details

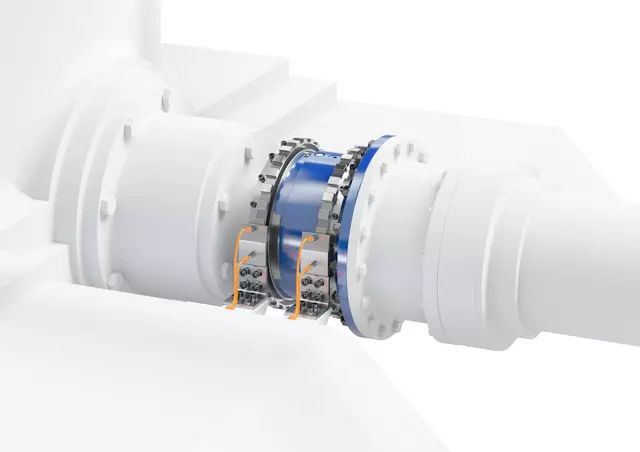

Voith's comprehensive product portfolio covers a range of torque limiting couplings with capacities from 1 to 20,000 kNm.

Tailor-made designs provide additional advantages to the production process. SafeSet, SlipSet, SmartSet, and AutoSet ensure the safe operation of the driveline by releasing or slipping at an exact torque level. In the event of a catastrophic, high-torque occurrence, the torque limiting couplings interrupt the power flow in the driveline, which minimizes damage and production downtime. The Voith Dtect System alerts you in real-time about torque overload situations, helping further protect your investment.

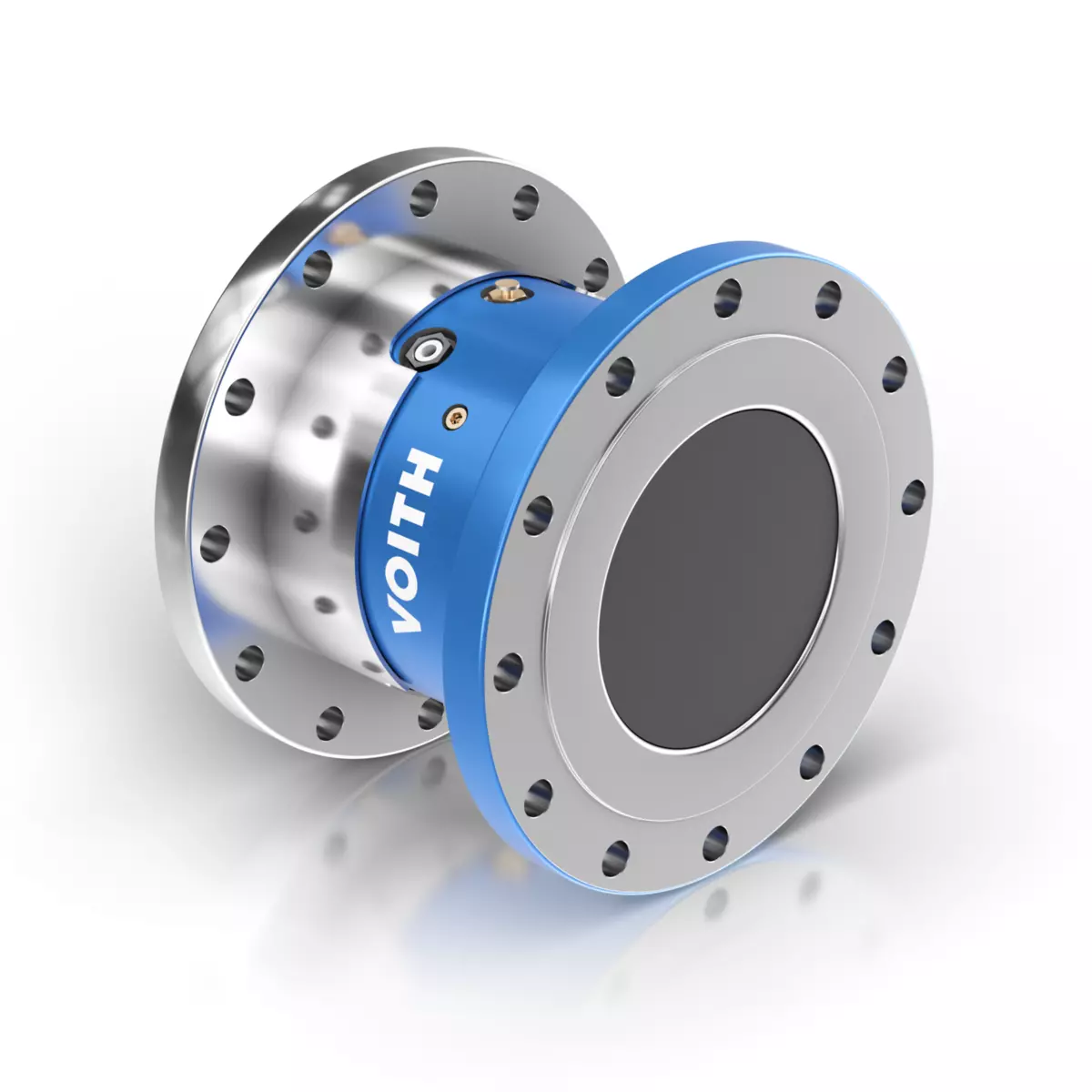

SafeSet – coupling with instant torque limitation and release

SafeSet protects your driveline and maximizes production.

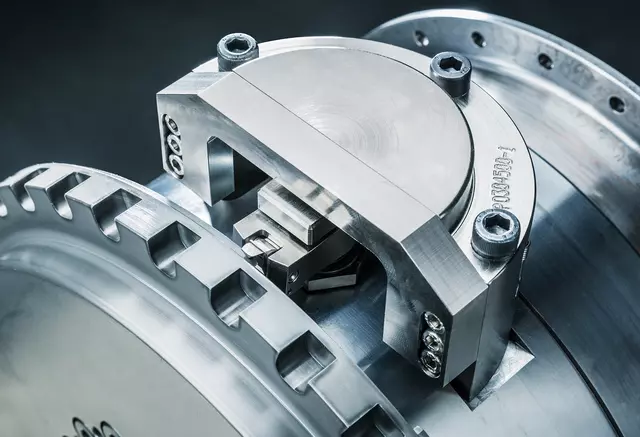

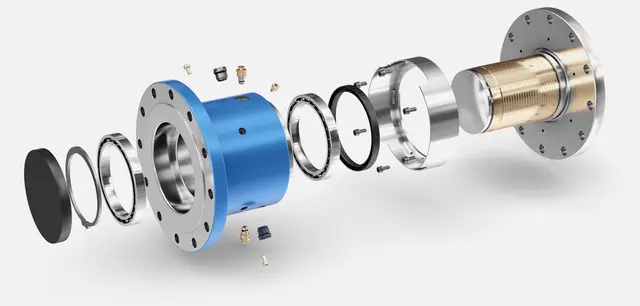

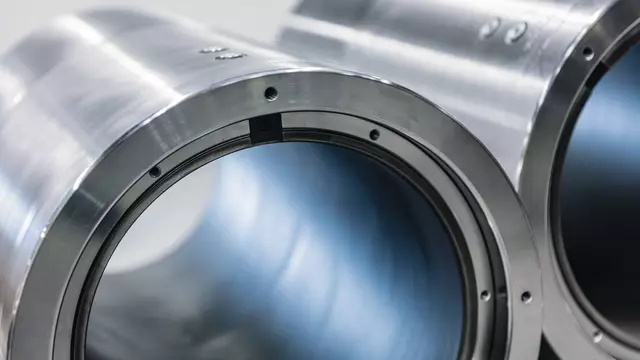

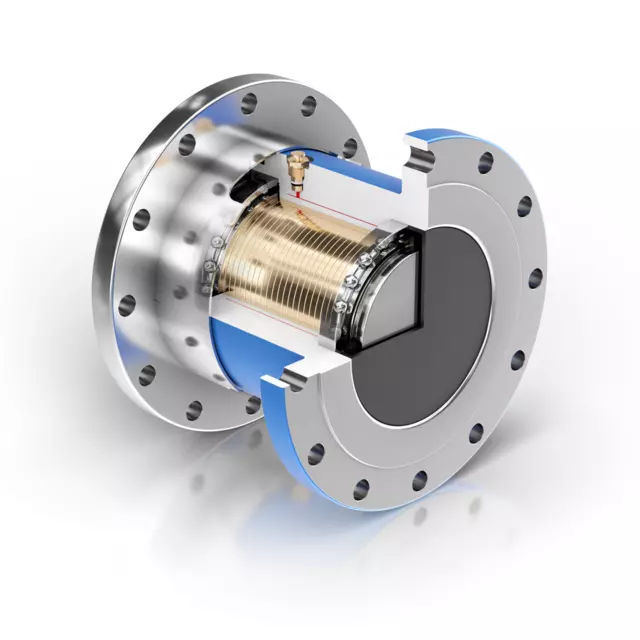

Protect your driveline and maximize production with a SafeSet. The principle is simple and based on friction and adaptability principles. No material fatigue or wear ensures constant torque protection during operation. The torque limiting coupling includes a twin-walled hollow sleeve. Friction is generated upon expansion by pressurized hydraulic oil. The integrated shear tube holds this pressure to ensure a constant but easy adaptable torque transmission. In an overload situation, the SafeSet slips, and the shear tube shears off. Oil pressure drops, and the frictional surfaces separate. Consequently, the SafeSet rotates on the bearings without transmitting any torque.

Features and benefits

Design features

- Torque range between 1 and 20,000 kNm, depending on model and use

- Adjustable torque settings to suit all applications

- Immediate release at a pre-set torque in the event of a torque overload

Benefits

- Maximum driveline protection — damaging inertia disengage at once

- Set torque remains constant over time

- Quick resetting for maximum uptime

- Custom-made to suit individual requirements

-

Torque limiting for increased performance in crushing SafeSet torque limiting couplings for belt drives and direct drives

PDFEnglish

SafeSet EZi – coupling for instant torque limitation with peak shaving

The next generation SafeSet torque limiting couplings enables maximum performance and ensures safety in tough environments.

Protecting your driveline and ensuring continued productivity is our specialty. Building on trusted technology with proven accuracy, our next generation of safety torque limiting couplings now include a peak shaving function. This improved release mechanism facilitates protection during short transient loads without releasing, whilst the wider slots together with the dual connection allows for quick and easy resetting. In order to improve efficiency and reduce maintenance time, a shear tube installation tool is included in your service box, simplifying the exchange of the tube, following an overload event.

Features and benefits

Design features

- Simplified resetting is facilitated by technical enhancements and a shear tube installation tool

- Release mechanism design enables peak shaving, without disengaging the coupling

- Add Dtect and monitor the status of your coupling in real time

- Plug-and-play package combinations of SafeSet EZi torque limiting coupling and highly flexible CT coupling available

Benefits

- Improved lead and delivery times, including spare parts

- Long service life of components with easy and quick maintenance

- Robust, reliable and proven technology perfected over 40 years

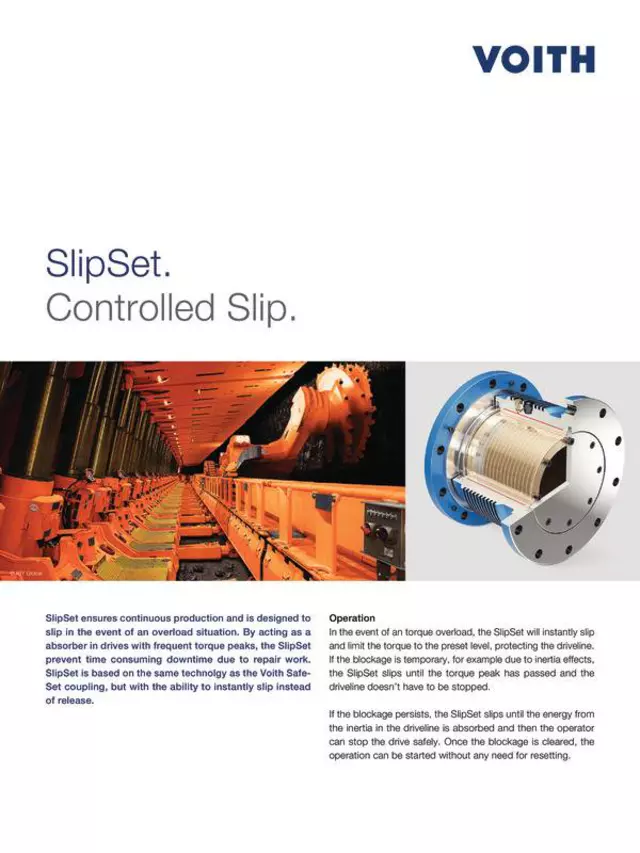

SlipSet – coupling with peak shaving

SlipSet is designed with the ability to slip instantly instead of releasing in the event of a torque overload.

Ensuring continuous production, the SlipSet is designed to slip in the event of an overload situation. Acting as a shock absorber in drivelines with frequent torque peaks, this torque limiting coupling safely prevents time-consuming repair work and shutdowns. This coupling is compact in design and can be installed in areas with limited space; this ensures optimal positioning in the driveline. The SlipSet torque limiting coupling is ideally suited for applications requiring short peak loads (smaller than slip angle 120°).

In a temporary torque overload, the coupling slips to limit the torque peaks and enables continuous production. If the blockage persists, the SlipSet coupling slips until the drive can be stopped for the obstruction to be cleared. To monitor the maximum slip angle possible, we recommend using the Dtect slip system.

Features and benefits

Design features

- Ideally suited for applications requiring short peak loads

- Adjustable torque settings from 50 to 100% of maximum torque setting

- Slip at a pre-set torque

- Immediate slip in the event of a torque overload

Benefits

- Ensures continuous production due to torque limitation without disengagement

- Minimized installation cost thanks to a compact design

- Less maintenance cost due to instant overload protection that protects your driveline from premature wear

SmartSet – coupling with peak ride through and controlled release

Torque limiting couplings from Voith prevent machine damage in high-value rotating equipment. They work like a mechanical fuse in the driveline by protecting the system from costly breakdowns.

SmartSet is a torque limiting coupling with controlled slip based on the same technology as SafeSet, with the additional ability to also slip without releasing, to reduce the short duration and dynamic torque peaks without interrupting production. The SmartSet principle is simple: controlled slip torque for process improvement. The SmartSet coupling can safely slip up to 120° without releasing to limit short peaks. If the torque peak is of long duration in an overload situation, the SmartSet coupling will fully release and save the driveline from severe damage.

Features and benefits

Design features

- Ability to slip up to 120° during a torque peak

- Adjustable torque settings from 50 to 100% of maximum torque setting

- Mechanical slip and release mechanism

Benefits

- Ability to slip without release to reduce the short duration and dynamic peak torques

- Precisely adjustable slip and release torque

- Maximum driveline protection

- Full release during blockage

AutoSet – coupling with peak ride through and automated reset

AutoSet automatically resets the pre-set torque limit after a longer overload/complete blockage.

Controlling the slip and automatically resetting to improve performance and minimize production stoppages, this process-improving torque limiting coupling handles dynamic torque peaks of short duration safely and without releasing. The AutoSet reduces high torque peaks by slipping up to 180°. If the torque peak lasts long, the coupling will release entirely, limiting the torque.

Features and benefits

Design features

- Ensures continuous production due to torque limitation without disengagement

- Complete disengagement during a long peak event

- Automatically resets itself to the pre-set torque limit after a longer overload/complete blockage

Benefits

- Improves production, as no resetting is needed for short peaks

- Lower maintenance cost with no manual resetting needed

- Less investment cost, as no additional equipment is needed

- Continuous operation, even during an overload, improves production uptime

Dtect – coupling monitoring system

Add Dtect for real-time driveline monitoring in order to prevent costly downtime with proactive maintenance.

Features and benefits

Design features

- Modbus TCP/IP standard

- Slip angle measurement

- Relay outputs

- Speed measurement

- Service indicator

- Ethernet connection

Optional features (on request)

- GSM module

- Multi monitoring

- Integrated HMI touch panel

Benefits

- Real-time monitoring of the driveline status

- Possibility to optimize driveline performance

- Integration with existing process monitoring systems enables platform-independent supervision of data

- Prevent costly downtime with proactive maintenance of a coupling

- Visual and audio warning indicators can be activated for making decisions and actions

- Increase uptime of the driveline

Areas of application

Rail vehicles and test rigs

Rail vehicles and test rigs

Prevent excessive torque and protect passengers in the event of failure. Mobility applications include:

- High-speed trains

- Test rigs

Marine technology

Marine technology

Protect drivelines and machinery from overload and ensure a smooth, reliable propulsion. Marine applications include:

- Propulsion

- Thrusters

- Water jets

- Ship loaders

- Dredgers

Energy

Energy

Limit torsional vibrations, protect the driveline, and provide a reliable release torque. Energy applications include:

- Gas turbines

- Compressors

- Wind power

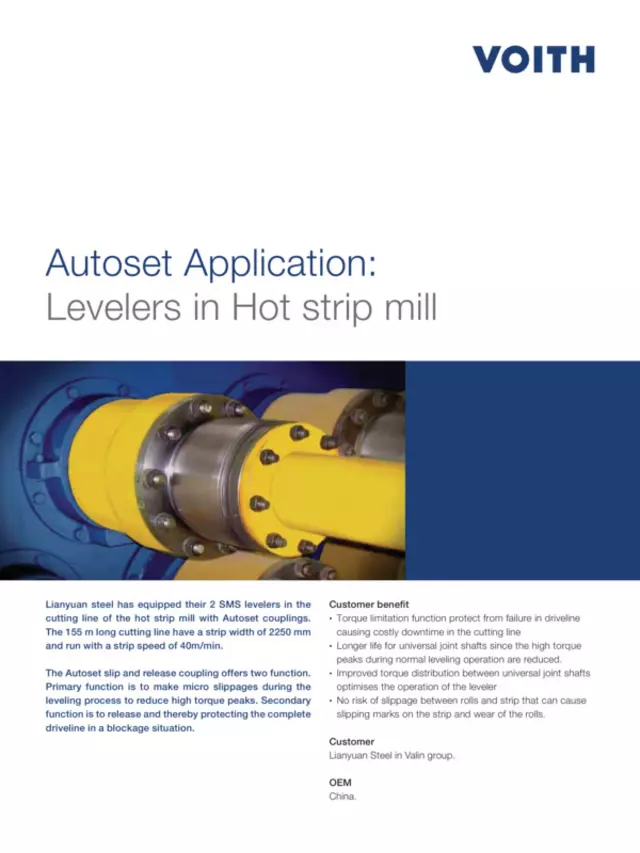

Steel and recycling

Steel and recycling

Protect machinery from damage by releasing or slipping at a precise set torque. Metals applications include:

- Levelers

- Rolling and Steckel mills

- Plate and strip mills

- Shredders

Mining

Mining

Protect machinery from damage by releasing or slipping at a precise set torque. Minimize operating downtime and increases production uptime. Raw materials applications include:

- Crushers and grinders

- Conveyors and excavators

- Mixers and extruders

Construction

Construction

Protect the driveline under excessive torque levels. Construction industry applications include:

- Tunnel boring machines