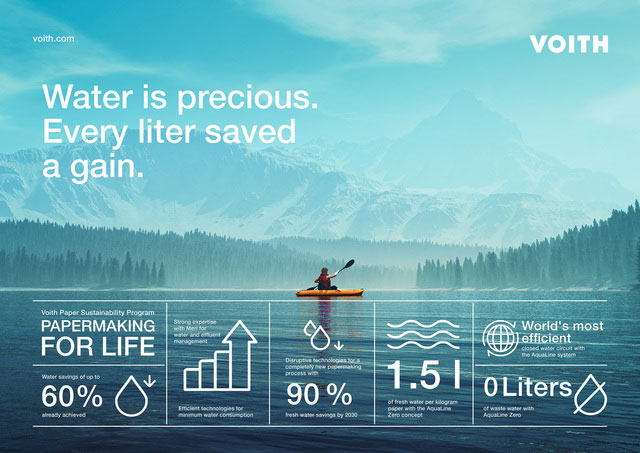

Water is precious

Every liter saved is a gain

In terms of water shortage, the requirements and water rights are becoming more stringent for paper mill operators at many locations. Especially in regions with water scarcity, closed water cycles are becoming increasingly important. We develop and deliver solutions that drastically reduce water consumption in paper production, primarily through the development of closed water loops.

Water savings

Water savings of up to 60% already achieved

Zero liters of process effluent

Zero liters of process effluent with immediate effect with AquaLine Zero

World's first closed water circuit

Most efficient closed water circuit with the AquaLine concept with minimized fresh and effluent water consumption

1.5 l fresh water per kg paper

AquaLine Zero reduces fresh water consumption to only about 1.5 liters per kilogram of paper produced

New, disruptive technologies

Disruptive technologies for a completely new papermaking process with 90% water savings by 2030

Strong expertise with Meri

Strong expertise with Meri for an optimized water and wastewater management

Our technologies

Our vision is to reduce fresh water consumption towards zero for all paper grades. The gradual switch to using purified and filtered water that is recirculated is the key to significantly reducing water consumption in paper production.

Proven success: We make our actions transparent

With this new sustainability report we are once again making our actions transparent. After all, our stakeholders decide whether our sustainability measures are successful: Their assessment forms the benchmark for our actions, as this reflects the effectiveness of our activities in the respective fields of action.

Would you like to learn more about holistic sustainability in paper production? Talk to our experts.

Peter Eisen

Senior Vice Product Management Digital Voith Paper

Bernd Güldenberg

Senior Vice President R&D Technology Voith Paper