Roll covers for every application

Roll cover technology is a key factor in improving sheet release, reducing draw, improving dewatering performance, ensuring consistent coating and sizing, and achieving excellent calendering results. The various applications on the paper machine require a variety of roll cover designs and coating materials.

Materials range from ceramic coatings to very soft elastomeric covers

The surface profiles range from plain polished to high open surfaces, as well as complex cross-machine direction crown designs. Contact us - together we will find the perfect roll cover for you!

Find your perfect roll cover

Forming

Roll covers in the forming section need to guide and tension the fabric.

Some of the rolls have to transmit the drive force to the fabric, while other rolls perform dewatering functions. The roll covers need to be doctorable and wear resistant, have good traction properties, and perform with no sheet marking. Voith offers roll covers in rubber, polyurethane, composite and resin, as well as hard metal coatings for the various applications in the forming section.

Roll types in the forming section:

- Breast Roll

- Couch Roll

- Forming Roll

- Lumpbreaker

- Table Roller

- Wire Drive Roll

- Wire Suction Roll

- Wire Guide Roll

Press

Roll covers in the press section must remove the remaining water via a system of nips pressing against each other, aided by press fabrics that support the sheet and absorb the pressed water.

High surface stability, no marking, sufficient operating volume, high wear resistance and impact resistance and doctorability are some of the necessary features a roll cover needs in the press section. Depending on the specific roll application, we offer polyurethane, rubber and thermal coatings.

Roll types in the press section:

- Center Press Roll

- Center Suction Press Roll

- Felt Guide Roll

- Glazing Cylinder Pressure Roll

- LNP Soft Roll

- Paper Guide Roll

- Pick-up Suction Press Roll

- Press Roll Hard

- Press Roll Hard Vented

- Press Roll Soft

- Shoe Press Counter-Roll

- Smoothing Press Roll

- Suction Press Roll

- Spreader Roll

Dryer

In this paper machine section, the paper web is heated with steam to reach the necessary dryness value.

In the harsh environments, cylinders and guide rolls are prone to contaminations and corrosions. They need special thermal and metal coatings for corrosion protection, as well as wear and contamination resistance. We offer specially developed coatings for all applications.

Roll types in the dryer section:

- Dryer Cylinder

- Dryer Wire Guide Roll

- Dryer Paper Guide Roll

- Spreader Roll

Coating & Sizing

For demanding print results that are brilliant in detail and require very smooth, closed surfaces, Voith Paper offers a wide range of roll covers for sizing and coating applications.

Using our sizing and coating roll cover knowledge combined with our expertise as a paper machine supplier, we are able to ensure the roll cover selected meets your expectations. Depending on the specific demands, we offer polyurethane and rubber roll covers.

Roll types in the coating and sizing section:

- Coater Applicator Roll

- Coater Backing Roll

- Paper Guide Roll

- Film Press Applicator Roll

- Spreader Roll

- Size Press Hard

- Size Press Soft

Calender

Product Selector

Find the perfect fitting roll cover for your calender

Thanks to our new Product Selector, you can configure your individual calender roll cover within a few steps. Together with our experts you will create a cover which is tailor-made for your application and priorities. As a result you not only increase the efficiency of your paper machine but also save money and participate always in the latest technology.

“Our focus are our customers and their needs. Therefore, they receive a product that is tailored exactly to their individual requirements.”

Ralf Moser, Global Product Manager Finishing Section & Doctor Blades

Depending on the purpose for which a paper is used, its surface must have certain properties – especially smoothness and gloss.

These properties are imparted to the paper by calenders, which are equipped with up to 15 rolls. Our calender roll cover product line offers an extensive cover choice for all application requirements. Optimized fiber-reinforced composite covers and world-class thermal coating covers provide optimum paper gloss, smoothness, and bulk while maintaining cover profile and surface consistency.

Roll types in the calender:

- Machine Calender Hard Coating

- Multi-Nip Calender Elastic Roll

- Mulit-Nip Calender Hard Coating

- Paper Guide Roll Calender

- Soft Nip Calender Elastic Roll

- Soft Nip Calender Hard Coating

- Super Calender Elastic Roll

- Super Calender Hard Roll

- Spreader Roll

Reeling & Winding

During reeling the paper web is wound up on reel spools.

We offer rubber or polyurethane covers on reel spools, providing a perfectly closed nip when starting the winding process on the spool and running smoother with reduced noise. During winding, the paper is cut into narrow rolls. Our polyurethane covers have superior cut resistance and remain in better condition for more consistent winding. We also offer thermal coatings that can be applied either on site or in one of our locations equipped with thermal spraying.

Roll types in the reeling and winding section:

- Reel Drum Hard

- Reel Drum Soft

- Reel Spool

- Rider Roll

- Squeeze Roll

- Winder Drum

Special

We offer excellent roll covers to meet the specific requirements for special applications.

Marking and splicing rolls are used for applications in which the roll covers must meet special requirements – such as very high wear resistance or a soft surface. For these special applications, we offer excellent roll covers.

Roll types for special applications:

- Marking Roll

- Splicing Roll

Tissue

Roll covers in tissue machines need to offer excellent wear and thermal resistance with high hardness stability to provide excellent operational safety.

Coatings for Yankee cylinders must withstand rough conditions and therefore offer high wear and corrosion resistance. Depending on the specific tissue machine requirements, we offer different covers and coatings.

Roll types in tissue machines:

- Tissue Pressure and Suction Pressure Roll

- Yankee Cylinder

- MG Cylinder

Diagnostic Systems

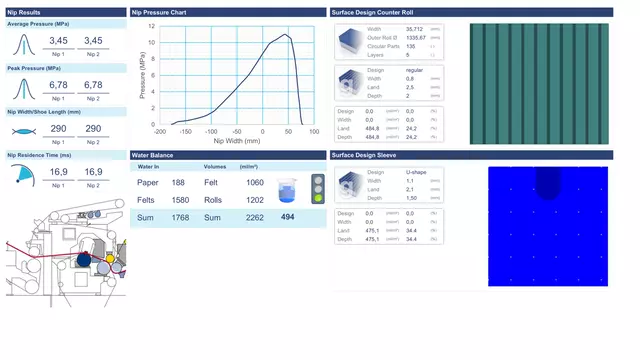

NipMaster analysis program for optimum dewatering

Designed for efficiency

The NipMaster concept exploits the surface design of suction and press rolls and comprehensively analyzes optimum dewatering characteristics.

NipSense2: Profile optimization through real-time measurement in the nip.

NipSense2 is a system consisting of mats with highly sensitive sensors that are inserted in the nip. The data of the nip width are transmitted wirelessly to a computer with special analytical software and directly displayed. Changes in the nip profile can thus be followed directly on the screen. NipSense2 visualizes possible discrepancies in the crown, the closing process and the hydraulic systems in real time and a correction calculation is carried out.

Voith’s NipMaster is the innovative solution for analyzing and optimizing shoe presses in papermaking.

Data-driven evaluations and simulations enable targeted improvements in efficiency, quality and sustainability in the press section.

How can we help you? Talk to your personal expert!

References

Voith's TerraSpeed Supreme and SkyTop Plus provide stable performance and operational reliability in specialty paper production of Koehler Kehl's PM 1

The German paper manufacturer Koehler Paper produces specialty papers at five production sites using state-of-the-art technology. In particular, the production of SD and thermal papers at PM 1 at the Kehl site is demanding, as special fillers and auxiliary materials, such as PCC, AKD, and coated broke are used here. Due to the technological challenges, Koehler Kehl decided at the beginning of 2019 to switch roll covers from competitors to the newly developed Voith roll cover TerraSpeed Supreme.

Successful performance of Voith´s new thermal protection coating TerraDry PN at the PM 4 of Hamburger Containerboard

Hamburger Containerboard, a producer of high-quality corrugated case material products for customers throughout Europe, has significantly reduced cleaning efforts during shutdowns and increased efficiency thanks to Voith's new thermal protection coating TerraDry PN.

Tissue mill awards long-term mechanical roll service contract and roll cover business to Voith based on performance

A Southern U.S. tissue mill, which produces virgin and recycled fiber products for both the consumer and commercial markets, recently expanded its relationship with Voith as the company proved its service excellence and quality product offerings.

Voith’s expertise and quality products deliver savings to U.S. tissue mill

A Midwestern U.S. tissue mill, which produces light, dry crepe tissue on a traditional crescent-forming machine, recently expanded its relationship with Voith as the company proved its service excellence and quality product offerings.

MegaFlow rubber roll cover delivers uniform profile and wear resistance to U.S. board mill

A board mill in the eastern United States was experiencing chemical degradation issues on its suction press roll cover. The MegaFlow cover from Voith solved these problems and showed a uniform profile from edge to edge over the front face of the roll, a greatly reduced cupping of the suction holes and no sheet marking.

SolarPress covers and Total Roll Management program revive board machine

The upgraded presses allowed for a boost in the solids coming out of the press section. Solids increased from 43 percent before the rebuild to 49 percent after the rebuild. Voith exceeded 100 percent of the project goal and was awarded credit for the project’s success. The machine set new all-time production records shortly after starting up from the rebuild.

combination for us.

How can we help you?

Our experts are happy to help you find the prefect roll cover for your application!