Press concepts

Best dewatering in class with proven shoe press technology

The main function of the press section is the mechanical dewatering of the paper web. Furthermore, the press configuration determines surface properties such as smoothness and two-sidedness. The goal in the press section is to achieve the greatest possible dewatering, since mechanical pressing is much more economical than drying by heat. In addition, the highest possible dry content contributes to higher web strength, so that the risk of web breaks during transfer to the dryer section and during the entire operation is reduced. The paper web enters the press section with a dry content of 15 to 22% and leaves the section with a dry content of 40 to 55%.

Since its first installation in 1984, the NipcoFlex module from Voith has proven itself in more than 620 shoe press installations. The decisive technological advantage of the shoe press is its high press impulse to the paper web. The combination of a long dwell time of the paper in the nip and optimal pressure gradients enables maximum production capacity at the highest quality level. Furthermore, NipcoFlex ensures that specific energy and production costs are minimized.

Key components

NipcoFlex module

The NipcoFlex shoe presses stand out due to their simple, reliable designs. The decisive technological advantage of modern shoe presses is their high press impulse to the paper web. The combination of a long dwell time of the paper in the nip and optimal pressure gradients enables maximum production capacity at the highest quality level. This optimal loading for paper dewatering is made possible by the combination of a position-stable backing roll and a hydraulically loaded concave pressure shoe under a flexible press sleeve of the NipcoFlex roll.

High paper quality

The design of the NipcoFlex shoe with top and bottom parts in combination with an insulation leads to low bending, excellent line load profiles and reduced maintenance effort. The hydrodynamic shoe design provides a gentle pressure buildup and high safety against crushing. Additionally, the NipcoFlex features a single pressure control system for simple load control.

High dry content & energy savings

Voith’s patented tilted press stack design offers maximum drainage performance with the lowest rewetting of felts on the market. The NipcoFlex module ensures efficient sleeve water removal due to the internal loadable support bar with dampening effect. The intelligent internal air/vacuum control assures high sleeve lifetime and best energy savings.

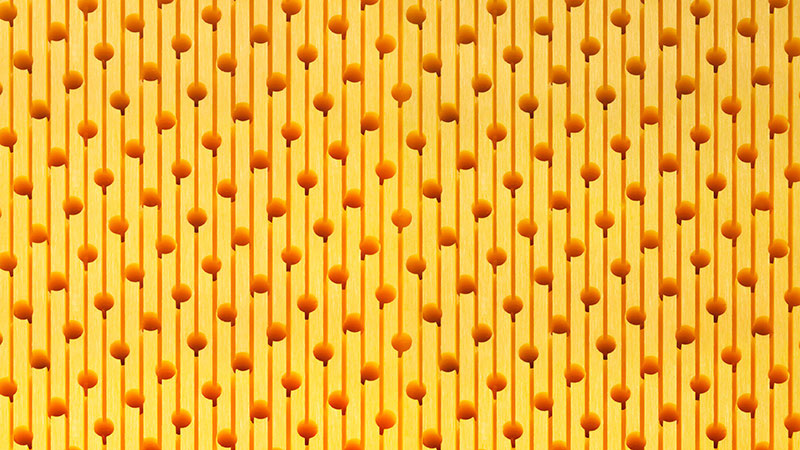

QualiFlex press sleeves

The requirements for press sleeves are different not just for every paper grade but also for individual machines. QualiFlex offers the best solution for this challenge: a product portfolio designed to fit general grade specific requirements, with several possibilities for further individual customization.

HydroSeal seal strip for all suction rolls

HydroSeal is the first to provide the option of dispensing with the conventional lubricating shower regardless of the type of suction roll or manufacturer.

Thanks to HydroSeal, the lubricating water is distributed continuously over the entire width of the seal strip, which allows the surface to be continuously covered with a homogeneous film of lubricating water. The efficient feed substantially reduces the amount of lubricating water required. Moreover, this new design prevents remoistening of the paper web and also improves the CD moisture profile.

ProTect press fabric measurement system

ProTect allows the precise measurement of fabric moisture and permeability at various points along the fabric. The system can be used with all commercially available manual measurement devices, but without the risk of endangering the maintenance team or service personnel. Thanks to its sophisticated design, all moving parts are predominantly outside the machine. This prevents wear and additional maintenance outlay.

OnQ ModuleSteam for controlled moisture cross profile in the press

The OnQ ModuleSteam controls the moisture cross profile in the press. It brings about high dry content, good moisture cross profiles and improved threading in the dryer section. Due to its small space requirement, it can be easily retrofitted into an existing press section.

Engineered for success

NipcoFlex increases production of board machine by 15 percent

The installation of a NipcoFlex shoe press was the first step in a comprehensive rebuild of the BM 1 at Macedonian Paper Mills (MEL) in Thessaloniki, Greece. This measure allowed the internationally operating manufacturer of board and packaging papers to increase machine production by 15 percent.

“With the new press section, we were able to improve board quality characteristics, reduce breaks and therefore significantly increase machine availability,” explains Georgios Georgiadis, the manager of the board factory.

Wanlida increases its production speed with NipcoFlex

In the shoe press upgrade on Wanlida Paper-Products Co., Ltd's BM 4 and BM 5 machines, the entire process from shutting down to restarting was carried out smoothly. The operating speed of the two machines went up by 50 to 80 m/min and the dryness of the paper out of the press section went up from 45% to over 50%, well surpassing the expectations of this Chinese customer.

NipMaster analysis program for optimum dewatering

Designed for efficiency

The NipMaster concept exploits the surface design of suction and press rolls and comprehensively analyzes optimum dewatering characteristics.