BlueLine DIP-processThe perfect stock preparation for white paper

Bright Fibers. Efficient Processes. Proven Technology.

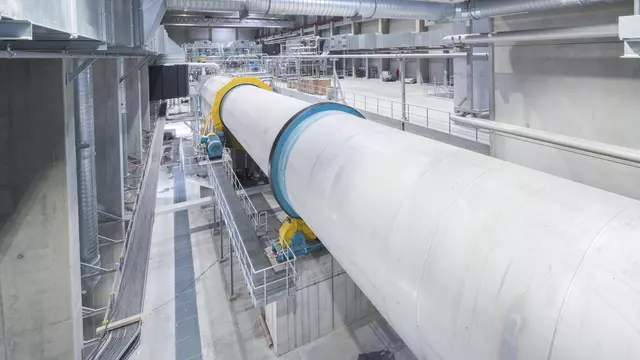

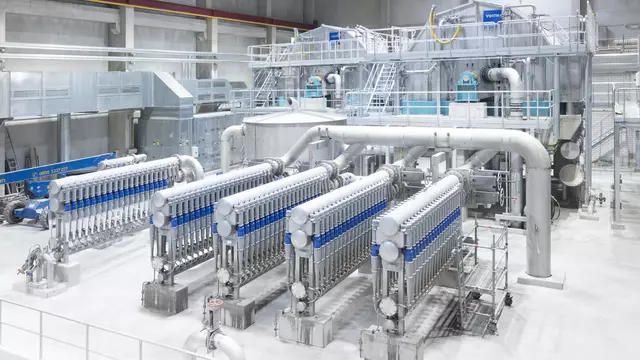

As a full-line supplier, Voith has been combining leading deinking technologies with a holistic understanding of the process for decades – from pulping to the paper machine. BlueLine DIP stands for excellent ink removal, stable whiteness, and minimal fiber loss, while at the same time requiring low energy and chemical consumption.

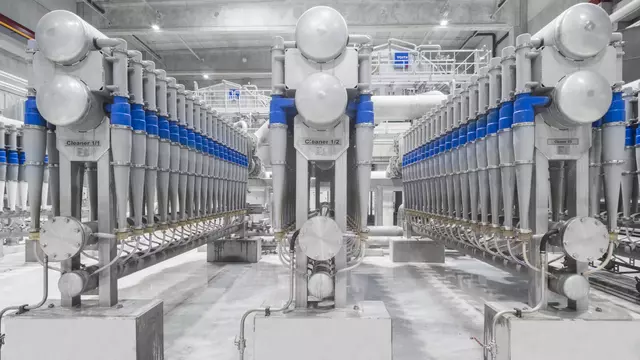

Voith develops customized deinking systems for a wide range of requirements – from graphic papers and tissue to white covered packaging papers and cardboard. Whether compact lines for smaller tonnages or large, multi-stage systems: With its comprehensive BlueLine portfolio, Voith offers robust, proven machines and innovative process solutions for every DIP application. The focus is always on low energy and maintenance costs, maximum operational reliability, and excellent runability.

Voith considers DIP stock preparation not only at the product level, but also and especially at the process level. With advanced technologies—from efficient flotation to intelligent cleaning and sorting to digitization and automation—we are setting new standards in the industry. This ensures a stable and high-quality supply of optimally processed fiber suspension to the paper machine, individually adapted to the respective raw materials and production targets.

Efficient fiber recovery and targeted broke preparation minimize production losses and reduce fiber losses to a minimum.

The result: maximum yield, maximum cost-effectiveness, and sustainable use of resources—for all DIP applications.

Maximum whiteness. Highest purity. Efficiently recycled.

Paper manufacturers worldwide rely on Voith BlueLine DIP systems when it comes to achieving excellent results with graphic and white-covered packaging papers. Our deinking solutions stand for maximum brightness, optical cleanliness and highest fiber yield – even with demanding raw materials and changing grades. Technologically leading components and intelligent process control ensure outstanding efficiency, low resource consumption and stable production quality. The result: Voith sets standards in quality, economy and sustainability – proven in numerous applications worldwide. See for yourself!

Söke PM 2

Schwedt PM 5