BeltGenius Conveyor Consulting: Expertise that drives belt conveyor systems forward.

In the mining industry, belt conveyors are absolutely essential for transporting the mined material. Every system is unique – adapted individually to the topography and diverse parameters of the specific site and required conveying capacity. Precise analyses and complex calculations are therefore necessary to design and plan new belt conveyor systems or optimize existing facilities. In addition, a high degree of human expertise and experience is important for the purposes of practical implementation.

The experts behind BeltGenius Conveyor Consulting offer both – the right tools and extensive expertise. The engineers are thoroughly familiar with all aspects of existing and planned systems and can use components that Voith Turbo develops and produces itself. As a result, the team has developed a profound understanding of belt conveyors and has incorporated this knowledge into the TurboBelt DriveControl control system, a development by Voith Turbo. TurboBelt DriveControl is the core of every belt conveyor system and ensures optimum operation. In the case of new systems and rebuilds of existing systems, the design of the drivetrain and programming of the system control unit are based on the actual needs of the system. Compared to competitors, Voith Turbo takes full responsibility from project planning of the conveyor to commissioning of the drivetrains, including the control system TurboBelt DriveControl. This reduces interfaces and project risk.

BeltGenius is the Voith Turbo product family that enables the monitoring of belt conveyor systems and thus provides the starting point for improvements.

BeltGenius Conveyor Consulting complements the BeltGenius product family

BeltGenius is the name of the Voith Turbo product family for monitoring conveyor belt systems, optimizing performance and design, and analyzing and resolving faults. This starts with sensors that collect and provide data on important belt conveyor components, regardless of whether these components are from Voith Turbo or other suppliers.

Apart from the reliability aspect, a wide range of improvements can be achieved with BeltGenius. Mine operators can rectify belt system problems, improve efficiency and increase productivity. Consequently, they can save CO2 and reduce their costs.

With the established software solution BeltGenius ERIC, a ‘digital twin’ for belt conveyor systems, important information can be obtained about whether the system is running optimally or whether there is room for improvement. “We are also working on solutions that will allow us to provide complete transparency about the belt system and its main components,” explains Stefan Hutzenlaub, Product Manager BeltGenius at Voith Turbo. “In this context, the main objective is to avoid unscheduled downtimes and make the replacement of components as predictable as possible. The result is a reduction of inventories, longer component service life, and optimal, condition-based maintenance planning. This in turn leads to considerable savings in the operation of belt conveyor systems.”

Stefan Hutzenlaub,

Product Manager BeltGenius, Voith Turbo

Service offering supports operators of belt conveyor systems

“With our new BeltGenius Conveyor Consulting service, we support our customers in optimizing their belt system not just in theory. They can maximize performance every single day – as efficiently and component-friendly as possible,” says Stefan Hutzenlaub.

Marco Dorigo, Vice President Belt Conveyor Systems at Voith Turbo, adds: “Belt conveyors are complex machines and no two are alike. The important factor when designing and optimizing such systems is the interplay between calculation software and the expertise of the user. Our experts know the limits of the mathematical models and extend them by applying their decades-long experience. Thanks to their practical knowledge, they know exactly how to avoid material spillages, for example, or how belt systems can cope even with narrow horizontal curves. They consider numerous details that are completely unknown to the software. It is only through the interplay of digital tools and our team‘s ideas that solutions are created which pay off for our customers in their challenging business environment every day.”

Marco Dorigo,

Vice President Belt Conveyor Systems, Voith Turbo

Voith Turbo belt system expertise

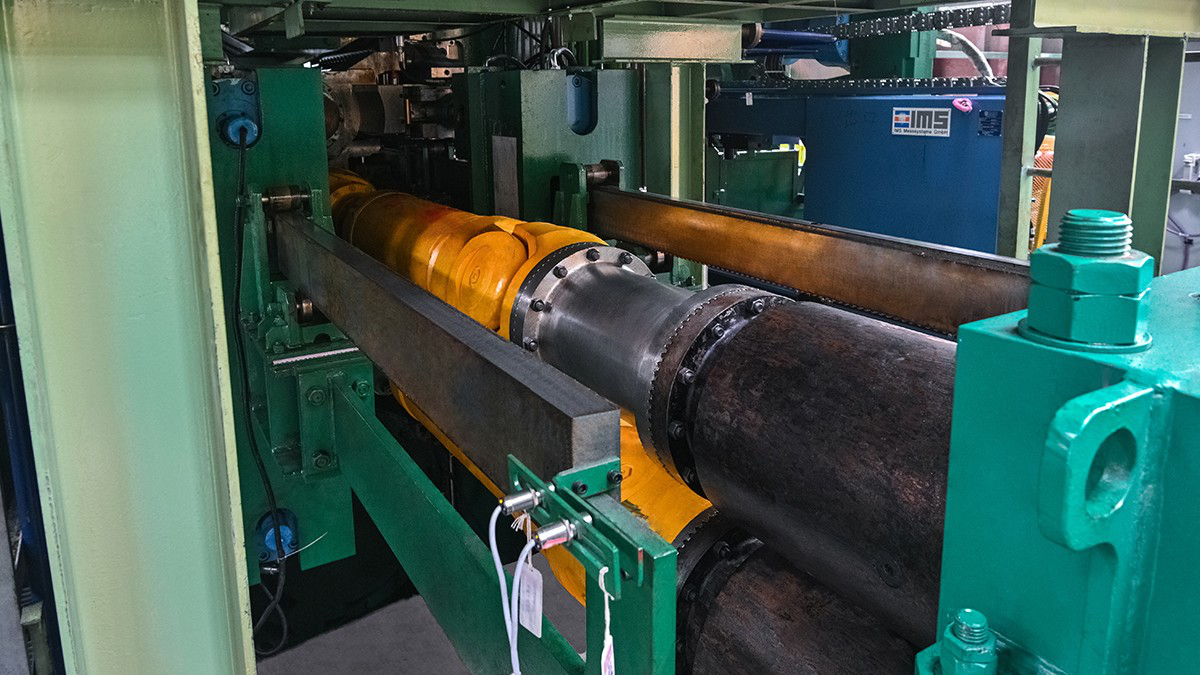

For many decades, Voith Turbo had been developing and producing components for belt conveyor systems. Its product range includes drive components like couplings, complete drivetrains, belt conveyor control system and conveyor belt pulleys. These products have proven effective worldwide under tough conditions in continuous operation and offer maximum reliability. This is not by chance, but the result of the intensive examination by Voith Turbo experts of the individual requirements of every single system.

Under the BeltGenius name, Voith Turbo brings together products and services that also enable the monitoring of belt systems, the optimization of performance and design, and the analysis and rectification of faults. This serves as the starting point for data-based process monitoring and optimization.

BeltGenius Conveyor Consulting makes knowhow accessible

This intensive engagement with the mining sector and with customers has not only led to an in-depth understanding of products and technologies but also of belt conveyor systems in general. With BeltGenius Conveyor Consulting, Voith Turbo is making this knowledge accessible, regardless of whether new belt conveyor systems are being planned or existing systems are to be improved.

Calculation software programs form the basis for the optimization of belt conveyor systems. For modeling purposes, Voith Turbo uses an IT solution developed in-house that is constantly being updated. Data from many different sources flow into the software. These include data from test rig measurements of real systems, scientific developments e.g. as part of doctoral theses, ongoing knowledge gains through BeltGenius ERIC projects, and extensive empirical values. As a result, the software provides unique and precise calculations that allow the experienced engineers at Voith Turbo to make suggestions for improvement based on a small volume of data on a belt conveyor system.

“For an even more extensive evaluation of data and root cause analysis, AI is indispensable,” explains Stefan Hutzenlaub. “In this context, the BeltGenius team can draw on Voith’s existing AI-assisted solution OnCare.InSight to adapt it for the specific use case.

Top-rate performance from a single source

When engaging Voith Turbo, customers benefit from the fact that from fault identification or project planning to commissioning, everything comes from a single source. This avoids inefficient and error-prone interfaces.

- System design/fault identification using BeltGenius Conveyor Consulting

- Project planning and manufacture or adaptation of suitable drivetrain

- Parameter setting of Voith TurboBelt conveyor controller, based on the simulation results of BeltGenius Conveyor Consulting, alternatively, adaptation of existing control system

- Commissioning of belt conveyor system

BeltGenius Conveyor Consulting in action for Südwestdeutsche Salzwerke

What can BeltGenius Conveyor Consulting do for a mine operator and its team? A great deal, as demonstrated by the results of a job done by our highly specialized team of experts for salt producer Südwestdeutsche Salzwerke. Working in a spirit of close partnership, a solution could be developed that improves efficiency, in particular by increasing the reliability of the belt conveyor system.