Voith BHS integral gear unit: Pilot project for the hydrogen future

Voith BHS integral gear units have become established over decades as reliable high-tech components in industrial applications. The increasing importance of hydrogen technology as a sustainable energy solution and key pillar of the global energy transition is now opening up new, extremely challenging rotordynamic applications. In this context, the pilot project to develop a special Voith BHS integral gear unit for hydrogen compression, currently with five pinion shafts (including the option for a sixth) marks an important milestone: It combines proven technology with innovative design to meet the requirements of the green energy production of the future.

Potential areas of application

The hydrogen industry and the number of potential application areas are growing exponentially – as is the demand for precise, durable and highly efficient drive solutions that are equal to the special challenges of this technology.

Likewise, the technical complexity of the housing design presented the development team with major challenges. With three split sections, the housing not only accommodates the five pinion shafts currently needed but also allows for the integration of a sixth shaft for future scalability – a key aspect for the long-term flexibility of the system.

Also noteworthy are the requirements for extreme precision due to the synchronous and sub-synchronous vibrations: At speeds of up to 50,331 rpm, the gear unit must not exceed a maximum vibration of just 12 micrometers – a value that is achieved by intricate rotordynamic calculations and a meticulous bearing design and that has already been successfully confirmed in a test run. By way of comparison: A human hair has a diameter of around 70 micrometers.

The following three requirements and criteria had been clearly prioritized by the customer from the very outset – and were ultimately impressively managed by Voith:

Another of the customer’s key requirements was to re-use proven components from earlier gear unit designs to build on tried and tested technology while integrating innovations. This called for a high degree of flexibility in the development process and comprehensive compatibility analyses.

Technical data

The relevant facts, figures and data on the new Voith BHS integral gear unit for hydrogen compression:

Maximum speed

The pinion shafts operate at an impressive 50,331 rpm

Precision

Maximum admissible vibration of just 12 micrometers – achieved by means of customer-specific bearing design and high-precision manufacturing

Configuration

Five pinion shafts with identical gear ratios, already prepared for a possible sixth pinion shaft in the event of future requirements

Design

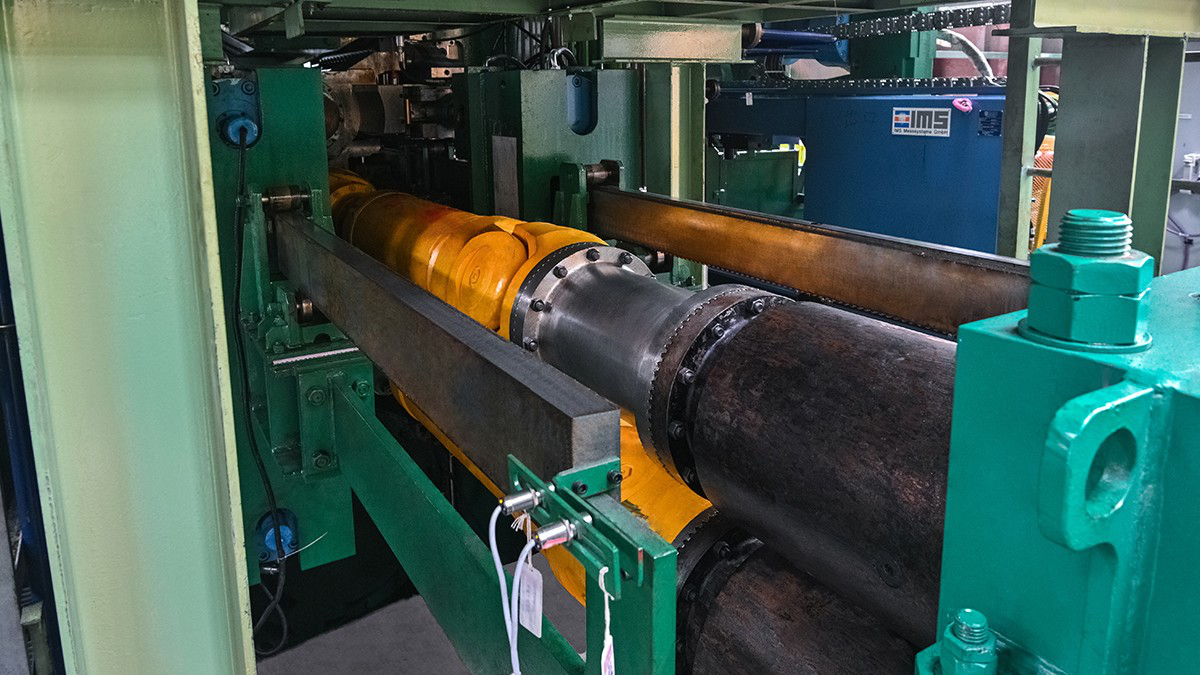

Extremely compact housing with three split sections, innovative reversed pinion shaft arrangement, and complex oil flow channels for optimum lubrication

Firstly, it plays a pivotal role in hydrogen production plants for generating green energy and thus directly contributes to the global energy transition. As a key component in one of the most promising technologies for the future it therefore underlines once again Voith’s innovative strength and focus on sustainability.

In addition, the gear unit was specially designed to drive a multi-stage compressor with five compressor stages and is optimally engineered for the extremely high speeds necessary for efficient hydrogen production. With rotation speeds of up to 50,331 rpm, it operates at the technological performance boundaries of modern drive technology.

A major benefit for plant operators like Linde is also the streamlining of the entire plant operation: “Reducing the number of necessary gear units not only cuts the investment costs but also the complexity of maintenance routines and the potential error sources in the system. This results in greater reliability and availability of the overall plant,” von Struensee emphasizes.

Here is a brief recap and overview of the major benefits of the new Voith BHS integral gear unit for hydrogen compression:

Reduction of plant complexity

due to the integration of two gear units in one system

Maximum precision and smooth running

even at extreme speeds

Future-proof design

with scalability option

Customized solution

to meet the specific requirements of hydrogen compression

Conclusion and outlook

The success of the innovative pilot project not only impressed Linde but also the existing customer base. It has also aroused the interest of new prospects. Several follow-up projects are currently being planned that will build on the insights and technological expertise gained. In this context, an important role is played by the option of integrating a sixth pinion shaft – but Voith’s known strengths in the reliable engineering of gear units and bearings continue to be very important. Because ultimately, these ensure that in terms of their rotor dynamics the gear units run smoothly without breakdowns and ensure low maintenance costs for the plant operator. Over the entire operating life.

The experience gained and technical solutions developed will now flow into the development of other customized gear unit technologies for the hydrogen industry – as a result of which Voith is already making an important contribution to the energy transition and creating a promising business field for the coming decades.